For an EMC/EMI Design and Test Engineer, one of the most frustrating and expensive problems is a unit failing EMC/EMI testing while at an EMC test facility (MIL-STD-461 and DO-160 Conducted Susceptibility, Conducted Emissions, Radiated Emissions and Radiated Susceptibility). While following good EMI design practices on a new design can result in a pass the first time, legacy designs, commercial off-the-shelf (COTS), and competing design priorities can result in failures from time to time. When a unit is failing conducted (CE102) or radiated emissions (RE102), there are not many hardware solutions that can be implemented for solving the problem in time to re-test before leaving the EMC test facility. However, EESeals® from Quell can help solve these issues and are available in just a few days after a design is finalized, most often free of charge. Powell Electronics will work closely with your design Engineers to understand what the EMI issue is that you are seeing and help you to understand what can be done using the EESeal to solve these issues.

What is an EESeal

An EESeal is an EMI Filter Insert (and Transient Suppressors) for connectors which are an easy retro fit compared to bulky adaptors, filter connectors and other traditional devices. The EESeal is made of resilient silicone rubber that is quick and easy to install, even in the field. Their patented construction allows them to survive even the most extreme environmental abuse. By using just your fingertip, you can easily install an EESeal insert into your connector in just seconds.

Virtually invisible once fitted, the EESeal inserts are made from the same super-resilient material used in the Interfacial seals of high reliability, ruggedized military connectors. The secret behind EESeal is Quells innovative electronic packaging technology, which suspends, isolates, and protects the discrete electrical components which are inside.

How It Works

Each individual EESeal is designed specifically for your application and is manufactured to fit your connector perfectly. Quell’s EESeal is silicone rubber packaging technology with 0402 and 0603 chip components placed directly into the silicone rubber, which protects and suspends the components so that they can withstand harsh, rugged environments such as those seen in military and aerospace applications. The compressive forces of the silicone rubber help maintain a reliable connection even under the extreme abuses that are common in such industries .This allows the EESeal to make a permanent and reliable contact with each individual pin and also the connector shell.

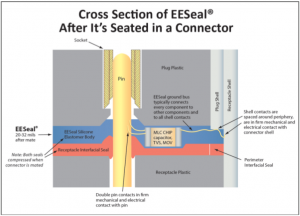

For a better understanding of how the technology works, we’ll take a look at Figure 1, a cross section of a mated pair of D38999 connectors. The blue portion that you see is an EESeal. Embedded in the silicone rubber is the 0402 and 0603 chip-device discussed earlier. Additionally, depending on the application, any of the following could also be included in the silicone rubber insert:

- Capacitor resistors

- Transient Voltage Suppressors (TVS)

- Multilayer Varistors (MLV)

- Any 0402/0603 or even some 0805 components can also be used depending on the connector size

Dual contacts are soldered on one end of the device that protrude into the hole. There are dual contacts on the backend that simulate a ground bus or, a spider web of a ground plane that will ground the shell contact or the receptacle, depending on the contact types or the connector’s needs. This system helps to build in a certain amount of redundancy into each EESeal where there are always 2 or more paths to GND.

All wires within the component are 3 mill, copper annealed, gold plated wires, making them more resilient than spring contacts. As you can also see in Figure 1, when a connection is made, the insert will take on the properties of the interfacial seal inside the connector, and in doing so it fills all the voids, nooks and crannies, maintaining the integrity of the interfacial seal itself.

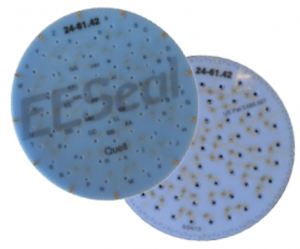

In Figure 2, you’ll notice that every device within the EESeal is discrete. The 0402 and 0603 type-devices are intentionally discrete, so every pin can be treated differently as needed in each application. As an example, because of this design you can have pins with unique attributes, for example:

- Pins 1-4 = 47 nanofarads

- Pins 12-15 = 220 picofarads

- Remaining pins = no capacitor fitted

Devices can also be designed in parallel or series, potentially allowing several chip devices to protect each pin, giving greater design flexibility

Multitude of Uses

Filter inserts can help overcome many challenges by providing:

- EMI filtering

- RFI filtering

- Transient protection for indirect lightning

- Transient protection for ESD

- The ability to add pull up resistors

- The ability to add grounding

- Redistribution of power

Because of its resistance to the effects of extreme environments, the EESeal is often used in performance-critical electronic devices found in military and aerospace systems. That said, the versatility of filter inserts is enough to bridge almost any connection where EMI/RFI is problematic, such as medical equipment or transportation products too.

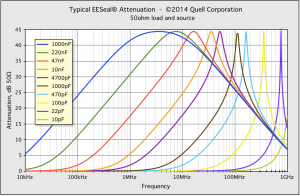

When speaking of EMI filtering performance, attenuation is the key metric. Utilizing the attenuation charts for various capacitances under a 50ohm load, such as those seen in Figure 3, the EESeal can mitigate frequencies from 10KHz to 40GHz. Chip capacitors range from 1pf up to 4.7uF These C-filter devices give a peak attenuation of approximately 40 to 45 dB at the peak frequency.

Customization

Every EESeal filter insert is custom designed which will ensure it meets your application’s specific EMI/EMC requirements.

In order for us to issue a quote, and to ship you a free of charge sample for testing purposes, we simply need the answer to the four questions below.

- What is your complete connector part number?

- Where are your EMI issues (scans are helpful)?

- What are the voltages on each pin?

- What are the maximum data rates on each pin? (e.g., RS232, Ethernet, video, etc.)

Further, if there are any special requirements such as meeting lightning specifications, we ask for the lightning pulse requirement such as found in DO-160 section 22 or MIL-STD 461G, CS117.

CONCLUSION

While filter inserts have been known as last-minute fixes for failed EMI tests, many designers are now using EESeals in their early designs. Some of the largest manufacturers in the world are now enjoying EMI/RFI filtration and transient protection without sacrificing space or weight. Integrating the EMI filtering solution into the connector allows room for other components or even further shrinking of the system itself.

Quell’s EESeal, can match and even exceed the performance of a traditional filtered connector while providing significant, tangible space, weight, and cost-saving benefits.

For more information, or to request a sample for your application please contact Powell Electronics EMI/Filter

Specialist – Andy Brayford

Global Applications Manager

Mob: +44 (0)7554 363639