UK-based Trackwise, an innovative manufacturer of limitless-length, multilayer flexible printed circuits, has just published ‘The engineers’ guide to multilayer flexible printed circuits (FPCs): technologies and applications’. This comprehensive white paper is packed with a wealth of information on FPCs and is an essential read for the electrical/electronic system designer about to embark on a project using FPCs or, indeed, anyone who needs to understand more about their benefits and applications.

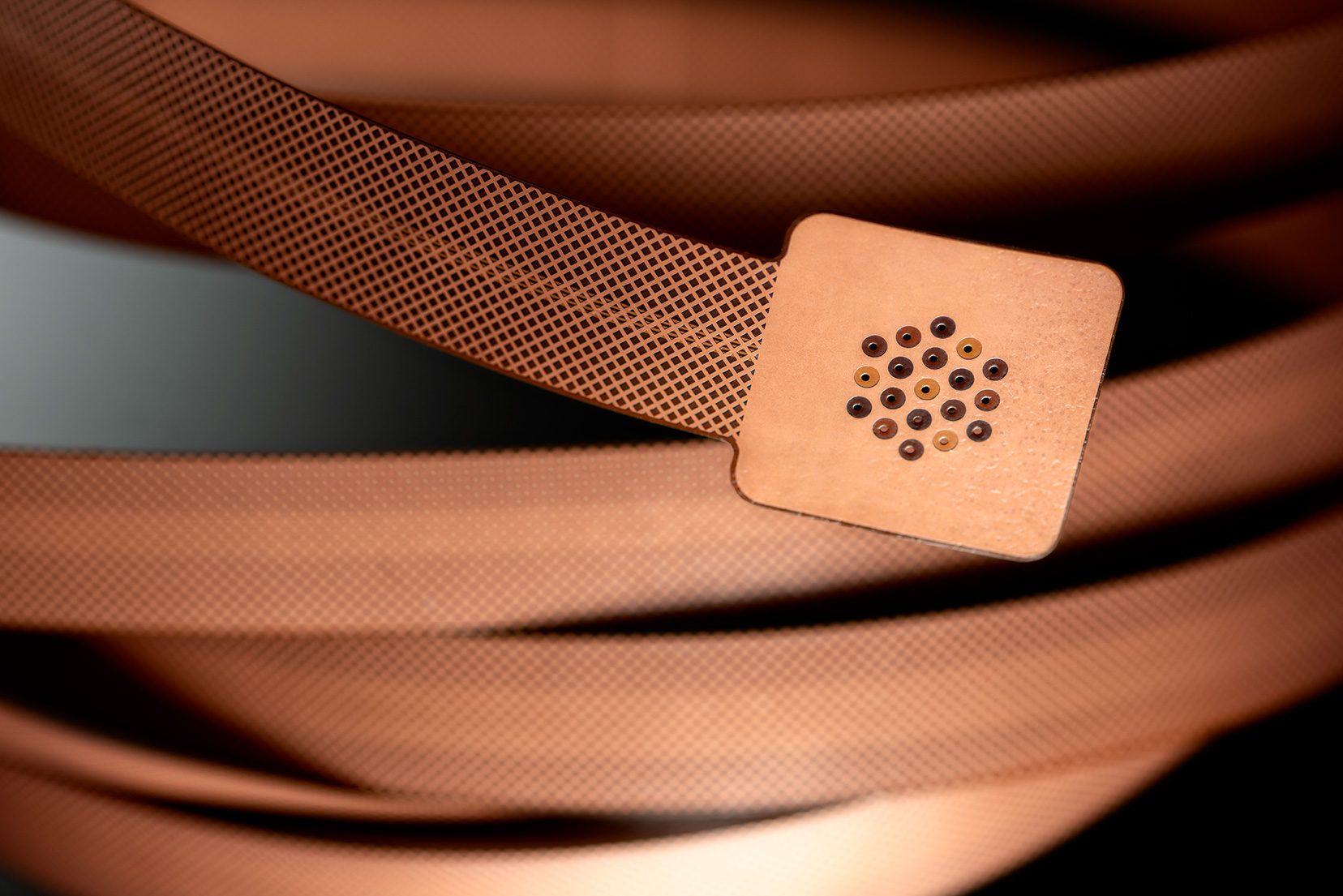

The flexibility of FPCs, coupled with their space savings and low cost, has seen their adoption in an expanding range of industrial and consumer electronic devices. However, traditional size limitations have restricted their use to relatively small devices, such as instrument panels, digital cameras, and wearable exercise monitors and healthcare devices.

This document explains how a new manufacturing process, IHT, has enabled the production of limitless-length FPCs, opening up their benefits to a much wider spectrum of applications, particularly those with strict space- and weight-saving requirements, such as in the aerospace and automotive industries.

By covering the fundamentals of FPC construction and describing in some detail the available configuration options and material choices, this new white paper enables the electrical/electronic systems designer to understand the benefits of FPCs and whether the technology is suited to the needs of a specific project. An essential read before embarking on a new design, the document describes in depth the six optional FPC types, and discusses the factors which determine their suitability for a particular application.

A detailed review of the materials available for each layer of the FPC, (base substrate, adhesive, conductor and cover-lay) guides the designer through the available choices, ensuring that the finished product will function as intended in its specific operational environment.

Said Philip Johnston, CEO of Trackwise, “FPCs are finding their way into more and more solutions and now, with the IHT manufacturing process, their benefits are available to many more applications, particularly in the automotive and aerospace sectors, where replacement of large and bulky wiring harnesses with flexible FPCs leads to significant space and weight savings. Our intent in publishing this white paper is to help our existing and prospective customers benefit from recent advances in FPC technology.”