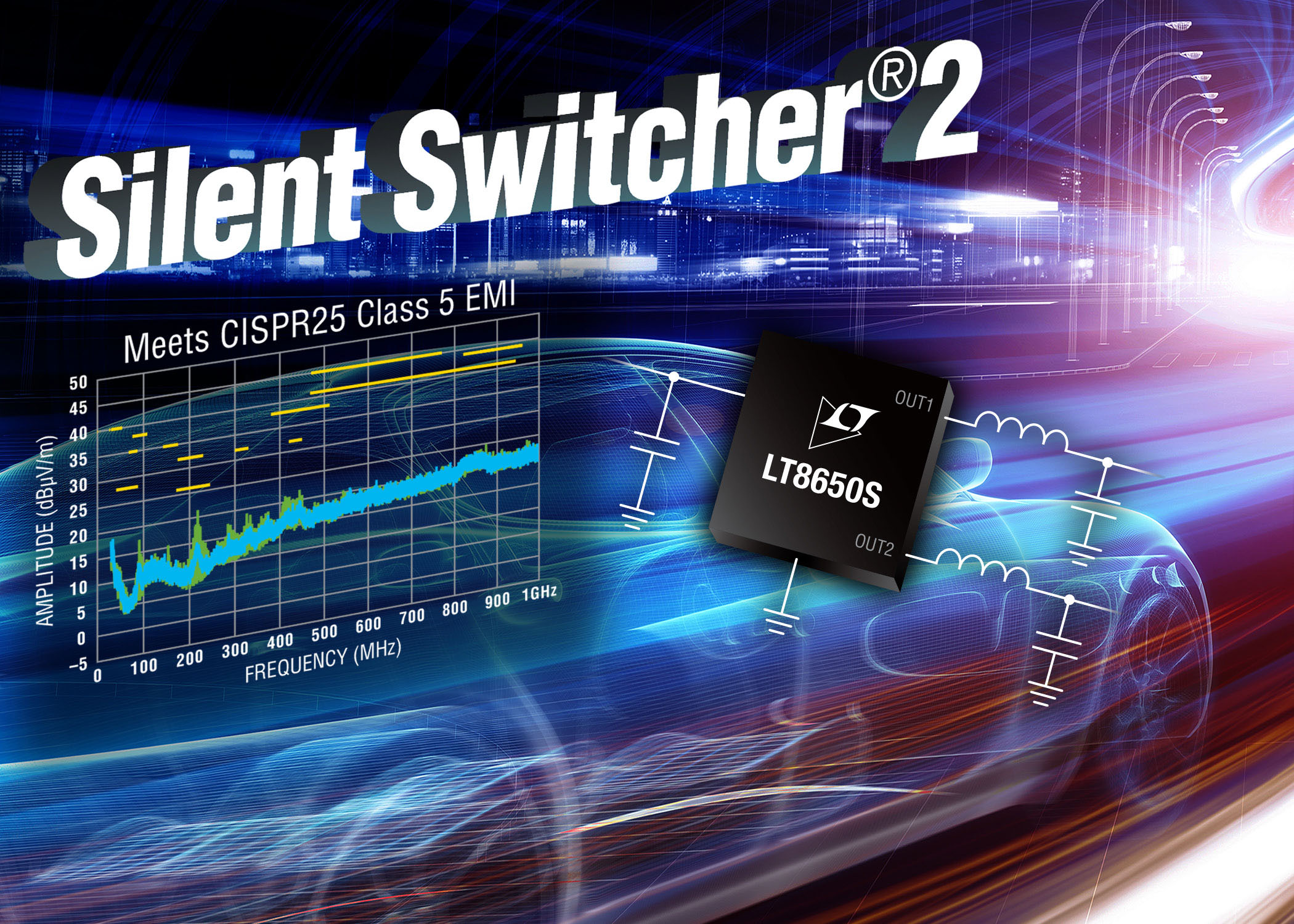

As the quantity of electronic systems in automobiles multiplies, so does the risk of intra-vehicle electromagnetic interference. For this reason, electronics in modern vehicles often must meet the CISPR 25 Class 5 test standard, which stringently limits conducted and radiated emissions. Switching power supplies, by their very nature, are rife with EMI, and proliferate throughout an automobile. Low EMI is now a key requirement for automobile power supplies, along with small solution size, high efficiency, thermal proficiency, robustness and ease-of-use. The Silent Switcher 2 regulator family meets the stringent EMI demands of automobile manufacturers while featuring compact size with integrated MOSFETs and high current capability.

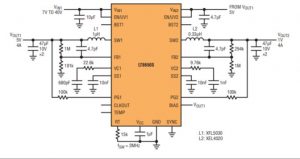

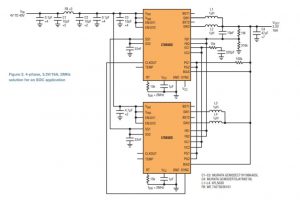

Figure 1. Dual output, 5V/4A and 1.0V/4A, using two

channels of the LT8650S

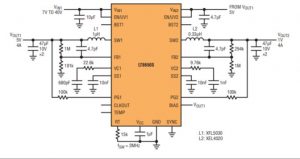

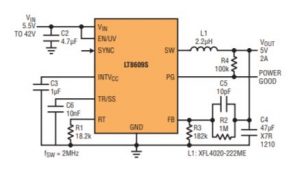

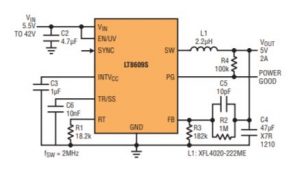

Figure 2. 4-phase, 3.3V/16A, 2MHz solution for an

SOC application

The patented* Silent Switcher technology enables impressive EMI performance in high frequency, high power supplies. Silent Switcher 2, the next generation of this technology, simplifies board design and manufacture by incorporating the hot loop caps into the packaging, so PCB layout has minimal effect on EMI (see sidebar).

Silent Switcher 2 Regulator Powers SOCs

The system-on-chip (SOC) devices found in today’s (and future) vehicles bear little resemblance to those of previous generations. Exponential feature expansion of infotainment systems and vehicle safety systems call for SOCs to process data several orders of magnitude faster than before, including processing high resolution video data from multiple sources with minimum latency. For example, if a car’s front camera “sees” a danger, the car must respond immediately, either warning the driver or applying the brake. To satisfy modern computational demands, SOCs squeeze an increasing number of power hungry devices into their packages, but how will that power be delivered? In an automobile, power delivery must be efficient, compact and low EMI. The increased power demands of SOCs makes meeting them more difficult.

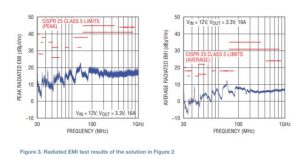

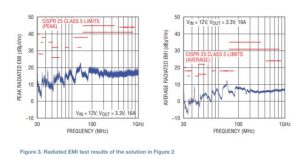

Figure 3. Radiated EMI test results of the solution in Figure 2

For example, an R-Car H3 SOC includes eight ARM cores, DSPs, video and graphic processors, plus ancillary support devices. Each of these components requires reliable power, including three rails (5V, 3.3V and 1.8V) for peripheral and auxiliary components, two (1.2 and 1.1V) for DDR3 and LPDDR4, and another 0.8V for cores.

To support the current levels demanded by SOCs, a switching power controller with external MOSFETs is the traditional choice over monolithic power devices. Monolithic devices are compelling because their internal MOSFETs minimize cost and solution size, but their traditionally limited current capability and thermal issues typically limit their use. The LT8650S and a new family of monolithic step-down Silent Switcher regulators have the current capability and thermal management features to support SOCs.

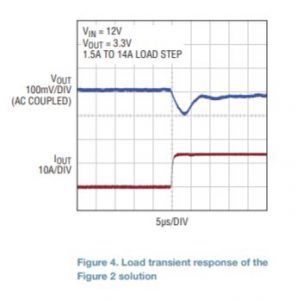

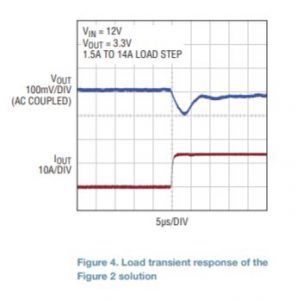

Figure 4. Load transient response of

the Figure 2 solution

The Power by Linear™ LT®8650S, LT8609S, and LT8645S have much higher output current capabilities than typical monolithic regulators due to high efficiency and thermal management features. Input voltage ranges from 3V to 42V (65V for the LT8645S) cover the spectrum of automotive battery conditions. These monolithic ICs have integrated MOSFETs and can run at greater than 2MHz, resulting in reduced solution size and cost while avoiding the AM band. Silent Switcher regulators are designed to minimize EMI, making them a popular

Figure 5. 2MHz 5V/2A application using the LT8609S.

choice for SOCs.

Dual Output: 5V/4A and 1V/4A

Figure 1 shows a dual output, 2MHz 5V at 4A and 1V at 4A, solution using two channels of the LT8650S. This circuit can be easily modified to fit other output combinations, including, for example 3.3V & 1.8V or 3.3V & 1.1V, to take advantage of the wide input range of the LT8650S. The LT8650S can also be used as the first stage converter, followed by various lower power second-stage switching or LDO regulators for more outputs.

The LT8650S features the EMI cancelling Silent Switcher 2 design with integrated hot loop capacitors to minimize noisy antenna size. This, coupled with integrated MOSFETs, enables exceptional EMI performance.

16A Solution for an SOC

Figure 2 shows a 3.3V/16A, 4-phase solution for SOC power. Figure 3 shows the radiated EMI test results.

Figure 6. Small solution size of the LT8609S

2-layer board

Automotive SOCs also place heavy demands on power supply load transient response. It is not uncommon to see a load current slew rate at 100A/µs for peripheral power supplies and higher for core supplies. Regardless of the changes in load, the power supply must minimize the output voltage transient. A fast switching frequency, such as the 2MHz capability of the LT8650S family helps speed transient recovery. Faster switching frequencies correspond to faster dynamic responses with proper loop compensation. Figure 2 shows the proper component values. It is also critical in board layout to minimize trace inductance from the output capacitors of the circuit to the load. Figure 4 shows the transient

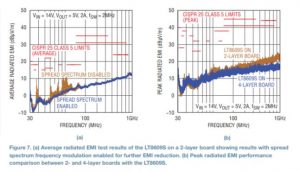

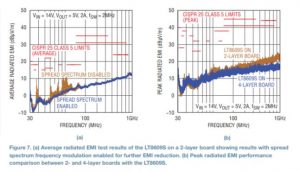

Figure 7. (a) Average radiated EMI test results of the

LT8609S on a 2-layer board showing results with spread

spectrum frequency modulation enabled for further EMI

reduction. (b) Peak radiated EMI performance comparison

between 2- and 4-layer boards with the LT8609S.

test results of the solution shown in Figure 2.

High Efficiency, Compact Solution for Lower Power Applications

In addition to the low voltage high current applications such as SOC and CPU, automobiles and other vehicles require power for numerous low current loads, such as dashboard instrument clusters, heads up displays, V2X, sensors, USB chargers, etc.

Due to the limited space and limited battery power, high efficiency and small solution size are top requirements for power converters. Low noise is a given. LT8609S is a suitable solution for all these applications. It’s designed with 3V to 42V input voltage range for automotive battery conditions. Integrated MOSFETs, built-in compensation circuit and 2MHz operation frequency minimize the LT8609S solution size. Silent Switcher 2 technology and integrated hot loop capacitors are used in the LT8609S to minimize noise levels and provide exceptional efficiency as well as excellent EMI performance. Figure 5 shows a 2MHz, 5V/2A application using LT8609S.

Figure 8. Thermal performance comparison between

2-layer and 4-layer boards with LT8609S

Figure 6 shows a complete LT8609S regulator on a 2-layer board. The integrated MOSFETs and built-in compensation circuit of the LT8609S reduce the component count to the device itself plus a few external components. Together with the high speed switching frequency, the total core solution size for this typical application is only 11.5mm × 12.3mm.

One way to reduce solution costs is to minimize the number of required PCB layers, but performance trade-offs are expected. For instance, a 2-layer board solution is not expected to produce equivalent EMI performance to a 4-layer solution. EMI results in Figure 7 show that the LT8609S on a 2-layer board satisfies CISPR 25 Class 5 EMI emissions. EMI performance is compared between equivalent solutions on 2- and 4-layer boards.

In general, Silent Switcher 2 technology yields excellent EMI performance with 2-layer boards and even single layer boards, which can greatly reduce manufacturing costs.

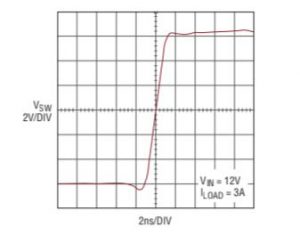

Figure 9. Monlothic Silent Switcher devices feature a MOSFET driver design that

produces fast, clean switching edges. This results in high efficiency, even at high

frequency operation. Innovative drivers also minimize overshoot, dampening

ringing that would otherwise be a source of EMI.

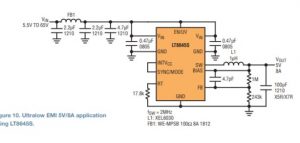

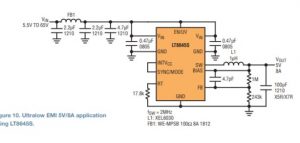

Figure 10. Ultralow EMI

5V/8A application using

LT8645S.

Thermal performance is usually a concern when fewer board layers are used, but not with the LT8609S. The Silent Switcher 2 technology’s low noise level and high efficiency have the benefit of low power loss from switching transitions. This, combined with an enhanced thermal dissipation package, enables the LT8609S to demonstrate impressive thermal performance. Figure 8 shows the thermal performance comparison between 2- and 4-layer boards. For 12V battery inputs, the LT8609S operates with less than

11°C temperature rise differential at full load.

Silent Switcher 2 Solution for 48V Automotive Systems

Conventional vehicles use 12V batteries to supply the power for ignition, lighting, audio and infotainment electronic devices, safety features, among other systems. Unfortunately, the power capability of 12V automotive system is limited to 3kW, a line that is increasingly challenged by the prolific number of automotive electronics.

This, along with the advent of electric vehicles and self-driving systems, challenges the norms of power delivery, with the automotive industry turning to 48V battery power as a solution. Compared to a 12V electrical system, a 48V electrical system reduces distribution losses when power demands are high, improving overall efficiency.

The challenge posed to DC/DC converters in 48V systems is to maintain conversion efficiency, size and low EMI similar to a 12V system, when high step-down ratios make it more difficult to meet these specifications. The gains made by using 48V should not be lost in the DC/DC conversion process. Monolithic switching regulators that can run at 2MHz to avoid interference with the AM band are ideal for 48V automotive electrical systems so long as they can do so efficiently.

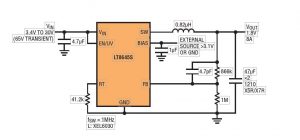

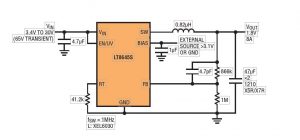

Figure 13. 1MHz 1.8V/8A application with up to 65V input transient

using the LT8645S

There are a limited number of monolithic buck regulators that can take 48V nominal inputs, most supporting less than 5A. The LT8645S monolithic buck regulator supports 8A loads, from input voltages up to 65V. Its 40ns minimum TON with fast clean switching edges (Figure 9) enable high switching frequencies and high efficiency, up to 94% at 2MHz.

Integrated compensation and bypass capacitors minimize the total solution size and simplify the low EMI layout. With a simple ferrite bead filter, the LT8645S can pass CISPR 25 Class 5 specs with margins.

Figure 10 shows an ultralow EMI 2MHz 5V/8A application using LT8645S. Figure 11 shows LT8645S efficiency and Figure 12 shows the LT8645S solution size.

The LT8645S has the unusual ability to support high step-down ratios even when operating at high switching frequencies, due to its 40ns minimum on-time. For example, the LT8645S can generate 1.8V from up to a 30V input at a 1MHz switching frequency. The input can go up to the absolute maximum rating of 65V if skipping switch cycles is acceptable.

When the output is lower than 3.1V, the BIAS pin of LT8645S should be connected to an external source that is higher than 3.1V, to improve efficiency. If such source is not available, tie the BIAS pin to GND. Figure 13 shows a 1MHz 1.8V/8A solution, that operates in the face of 65V input transients.

In addition to low EMI, high efficiency at high frequency, and a wide input voltage range, LT8645S features ultralow quiescent current and low dropout. The ultralow quiescent current can extend the battery run time in idle. The low dropout feature is critical to continuous operation in cold crank conditions.

Conclusion

Silent Switcher and Silent Switcher 2 regulators meet the demanding EMI emissions requirements of automotive environments. See Table 1 for a list of Silent Switcher devices, including those presented here.

Of the parts highlighted here, the LT8650S dual-channel synchronous monolithic Silent Switcher 2 regulator offers SOC applications a wide input voltage range, exceptional EMI performance, and small solution size, while providing multiple high current outputs and fast transient response. The LT8609S synchronous monolithic Silent Switcher 2 regulator offers a wide input voltage range, low quiescent current, excellent EMI performance, small solution size and high efficiency—it easily fills the ubiquitous power systems found in today’s automobiles. The LT8645S (inputs to 65V) enables compact low EMI solutions for 48V automotive systems. n