Advantech’s* Intel® processor-based intelligent gateway and SUSIAccess* software deliver a factory automation system that connects factory devices to the cloud.

Executive Summary

Equipment maintenance personnel are tasked with keeping the production line running at peak performance while minimizing operations costs. This is made more difficult by the need for specialized skill sets to support a wide range of factory devices that use different communications protocols, data formats, and device management tools, etc. Greatly simplifying this task, it is possible to seamlessly

link factory floor devices and processes using technologies from the Internet of Things (IoT), thus enabling remote equipment monitoring and management from a centralized dashboard.

Providing such a solution, the SUSIAccess* remote management system from Advantech* allows maintenance personnel to perform equipment status and maintenance checks from a web browser at any time, from anywhere, and with any connected device. The factory automation solution uses an Intel® processor-based gateway running an Advantech client-side agent to transparently handle protocol and data conversion, and acts as a conduit between manufacturing equipment

and the Advantech server-side software. This solution can interoperate with high-level applications such as data analytics and machine learning. This paper details the benefits and the key ingredients of the solution.

Key Business Objectives

Increase production line performance and reduce operations costs without sacrificing quality.

Business Challenge

Although large manufacturers have been using statistical process control and statistical data analysis to optimize production for years, the extreme complexity of today’s data provides

opportunities to deploy new approaches, infrastructure, and tools. The challenge

is figuring out how to cost-effectively unify device management, control, and data analytics.

In addition, manufacturers need a real- time device management platform that enables them to address maintenance issues on a timely basis. Today, there are many disparate manufacturing systems with their own management tools, which makes maintenance cumbersome and time consuming.

Solution Beneits

Revolutionizing factory equipment management in the IoT era, the Advantech SUSIAccess remote management system delivers the following advantages:

- Reduced Total Cost of Ownership (TCO): Saving time for maintenance personnel, centralized remote monitoring continuously checks factory floor devices and sends alerts to their mobile devices as needed. Power usage may be lowered by automatically powering systems on/ of according to a preset schedul

- Improved Production Line Performance: Machine data aggregated by the SUSIAccess server is processed by big data analytics to uncover ways to increase product yields, improve

predictive maintenance, and identify manufacturing problems more quickly.

- Easy Integration: The solution provides a comprehensive, seamless, device monitoring and control system that includes both hardware and sof

- Higher Equipment Availability: If a system fails, the keyboard-video- mouse (KVM) feature enables remote diagnosis and recovery for most software issues, enabling factory devices to be brought on line much faster and at lower cost than sending a technician onsite.

Solutions can be tailored to meet the specific requirements of

Figure 1. High-Level Structure of Factory Automation Solution

different factory environments given Advantech’s comprehensive system integration experience. Founded in 1983, Advantech is a leader in providing trusted, innovative hardware and software products, services, and global logistics support.

Solution Overview

Advantech has taken its turnkey solutions for factory automation to a new level by incorporating IoT

technologies as the foundation for a cloud-based platform running data analytics, remote management, and a wide range of third-party applications. This is done with a cloud management framework consisting of three layers – web-based Console, Server, and Agent

– as illustrated in Figure 1.

- Agent: SUSIAccess client-side software runs on Advantech IoT gateways or IoT devices (e.g., automation controller, edge computer, and sensors/actuators) on the factory floo

- Server: A central control room or a cloud-based service, such as Microsoft* Azure* and Amazon* Web Services, runs SUSIAcess server-side software that is in direct contact with agents.

- Console: A web-based interface that communicates with Agents via the Server, presenting IoT device status and configuration d

Solution Capabilities

The Advantech Smart Production Line solution provides a range of powerful features to monitor factory devices and perform remote operations.

- Centralized Remote Management The Advantech Console-Server- Agent structure allows administrators to perform device status and maintenance checks – at anytime

and from anywhere – via the web browser-based SUSIAccess console. Administrators can easily manage all of their devices by simply using their PCs, smartphones, and tablets. The solution also provides a distributed connectivity structure, which

solves the challenges brought on by large-scale or multi-site device management.

2. Hardware and Software Monitoring

SUSIAccess ensures Advantech

device stability by actively monitoring temperatures, fan speeds, voltages, hard disk states, and other hardware

elements, as shown in Figure 2. Active alerts are sent out if any abnormalities are observed, which can trigger user-defined actions, like stopping or restarting processes.

Available out of the box, device- side software uses a SUSIAccess API to send device status data to SUSIAccess.

In addition to the hardware monitoring functions, SUSIAccess also performs software monitoring by continually checking program status. Real-time alerts are sent out if any abnormalities are observed. Active management of both hardware and software can prevent serious damage to devices, thus

avoiding costly repairs and effectively

reducing the cost of ownership.

- User Friendly Map-view Interface Maintenance personnel can more easily locate and manage their devices using the map-view interface on SUSIAccess. In addition to the maps, building diagrams are provided to

help pinpoint device locations in

offices, factories, or wherever.

Figure 2. Centralized Remote Monitoring

4. Data Analytics

The SUSIAccess Server software runs on a variety of cloud computing platforms, including Microsoft

Azure and Amazon Web Services. These platforms typically include application support for data analytics, machine learning, video recognition, SCADA, business intelligence, and more.

5. Secure Interfaces

The Server-Agent connection is based on the MQTT communication protocol, which offers secure

and stable communications and decreases SUSIAccess integration time. The connection is also protected by OpenSSL.

6. Cost Savings1

SUSIAccess Server software is provided free, and SUSIAcess Agent software is preloaded on all Advantech solutions. In addition,

SUSIAccess will open the Agent source code and RESTful API document to non-Advantech platforms.

Customers can save up to 30 percent on deployment costs with worry-free compatibility and zero integrated software license fees. Maintenance costs can be reduced by up to 50 percent with the remote diagnosis and recovery capabilities. Real-time remote monitoring and proactive alarm notifications can bring down the time required for trouble shooting by as much as 70 percent.

Technology

This section describes the technology ingredients available to deploy a manufacturing solution like the one previously described.

IoT Devices

Advantech is a global leader in remote

I/O modules, offering complete,

stand-alone data acquisition modules, which are broadly used in IoT or

other industrial applications, such

Figure 3. UTX-3115 IoT Gateway

as facility monitoring, environment monitoring, and industrial process control. Advantech distributed remote I/O modules are categorized into two families, Ethernet I/O (ADAM-6000 series) and RS-485 I/O (ADAM-4000 series), which are subdivided into Analog I/O and Digital I/O modules.

Advantech also offers a complete range of embedded automation computers with each series coming in three sizes

– palm, small, and regular – all of them providing fanless, industrial-proven, application-ready control platforms.

IoT Gateway

Pictured in Figure 3, the UTX-3115 is a member of the Advantech Embedded IoT Gateway series, designed for efficient, stable, and 24/7 operation. Equipped with a dual-core Intel® Atom™ processor E3826, the gateway is built with extremely reliable hardware and

is easy to integrate with back-end maintenance and operating systems.

The UTX-3115 is based the Intel® IoT Gateway, which is a proven,

application-ready platform with pre- validated, industry-leading software. Integrated and validated components provide maximum flexibility, and fast application development and field deployment. The Intel IoT Gateway is built on open architecture to ensure interoperability between systems, enable wide application development, and simplify services deployment. The UTX-3115 IoT gateway includes Wind River* Intelligent Device Platform (IDP), which is a complete software development environment used for building IoT applications and devices that communicate with the cloud. It provides building blocks components to secure, manage, and connect IoT gateways to the cloud and is based on Wind River industry-leading operating systems, which are standards- compliant and fully tested.

SUSIAcess*

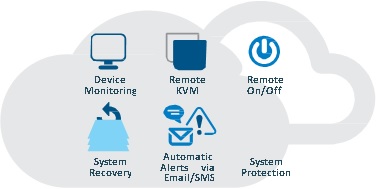

SUSIAccess Server software delivers IoT Cloud capabilities that provide real-time hardware and software monitoring and maintenance with key features shown in Figure 4 and described in the following:

- System Backup and Recovery: Powered by Acronis* Backup and Recovery technology, this feature performs regular, automated backups with dynamic scheduling, hot backup without interrupting current tasks, and differential backup used to save precious storage space.

- Remote Monitoring: Administrators can monitor remote device status, including hard disk temperature, hard drive health, network connection, system/CPU temperature, system/ CPU fan speed, and system voltages.

- System Protection: McAfee Embedded Control security software maintains the integrity of the Advantech embedded systems by only allowing authorized code to

run and only authorized changes to be made. It automatically creates

a whitelist of the authorized code on the system. Once the whitelist is created and enabled, the system is locked down to the known good

baseline, no program or code outside the authorized set can run, and no unauthorized changes can be made.

- Remote Keyboard-Video-Mouse (KVM): Administrators can use their consoles to control and display the

Figure 4. Key SUSIAcess* Functions

graphical user interface (GUI) of an IoT device on the factory loor

using Keyboard-Video-Mouse (KVM) redirection. No additional hardware is required. Administrators can control a device as if they were sitting right in front of it. Remote KVM is a feature in Intel® Active Management Technology (Intel® AMT),2 which also enables administrators to diagnose and repair devices remotely, thereby significantly lowering support costs.

For instance, it is possible to remotely remediate and recover systems after an operating system or driver failure.

- Remote On/Of: Administrators can switch IoT devices on/of based on a preset schedule.

- Automatic Alerts by Email/SMS: SUSIAccess actively sends alerts so administrators can receive real-time notifications of IoT device status through email or smartphone.

IoT Tenets

The Advantech SUSIAccess remote management system is designed to provide security and interoperability from edge to control center or cloud in keeping with five key tenets defined by Intel:

- World-class security as the foundation

- The solution implements robust hardware and software-level protection that secures data between IoT-based factory devices

and the cloud.

- Automated discovery and provisioning of edge devices to ease deployment

- SUSIAccess discovers and provisions Advantech devices on the factory f

- Data normalization through protocol abstraction to improve interoperability

- The Advantech IoT Gateway supports and abstracts a wide range of protocols, including MQTT, TR- 069, OMA, OSGi, Wi-Fi, and ZigBee*.

- Broad analytics infrastructure from edge to cloud to realize customer value

- The web-based Console-Server- Agent structure of the Advantech solution enables users to aggregate and move data from factory loor to analytic applications.

- Infrastructure to monetize hardware, software, and data management from edge to cloud

- This cloud-based solution provides the tools needed to realize substantial improvements in manufacturing performance.

Summary

Bringing the power of IoT to factory automation, Advantech’s SUSIAccess solution is able to help manufacturers improve the production line performance and lower operations costs by connecting factory devices to the cloud. The solution is made

up of client-side agent software and server-side management software that enables seamless device interconnection and easy-to-use management interface. Using this tool set, customers can save time when resolving device maintenance issues and, most importantly, reduce the total cost of ownership (TCO) of factory equipment.

The solution features a streamlined interface designed to offer a smooth, intuitive experience, making it easier for administrators to get up to speed right away. As a result, equipment maintenance personnel will find it much easier to use big data analytics to improve manufacturing performance and remote device monitoring to reduce support costs. Advantech, working with Intel, is incorporating IoT technology to enable new opportunities on the factory floor.

Resources

Intel® Internet of Things Solutions Alliance

Members of the Intel® Internet of Things Solutions Alliance provide the hardware, software, firmware, tools, and systems integration that developers need to take a leading role in IoT.

Intel® Gateway Solutions for the Internet of Things Development Kits

Intel Gateway Solutions for the Internet of Things development kits enable solution providers to quickly develop, prototype, and deploy intelligent gateways. Available for purchase from several vendors, the kits also maintain interoperability between new intelligent infrastructure and legacy systems, including sensors and data center servers.