Portsmouth, UK, 24 June 2021 – To provide customers with greater choice and increase design flexibility, Harwin now offers rear panel mount cable connectors for both its 2mm-pitch Datamate and 1.25mm-pitch Gecko high-reliability (Hi-Rel) series. These will complement the company’s existing front panel mount solutions, broadening the scope of how connector housings are attached to an enclosure or panel.

The clear advantage that rear panel mount has over front panel mount is that the bulk of the connector housing is located on the inside of the enclosure or panel. This means that the connector is much better protected from the external environment, with just its mating face being exposed. As a result, there is less risk of potential interconnect damage occurring, and the overall design looks better aesthetically.

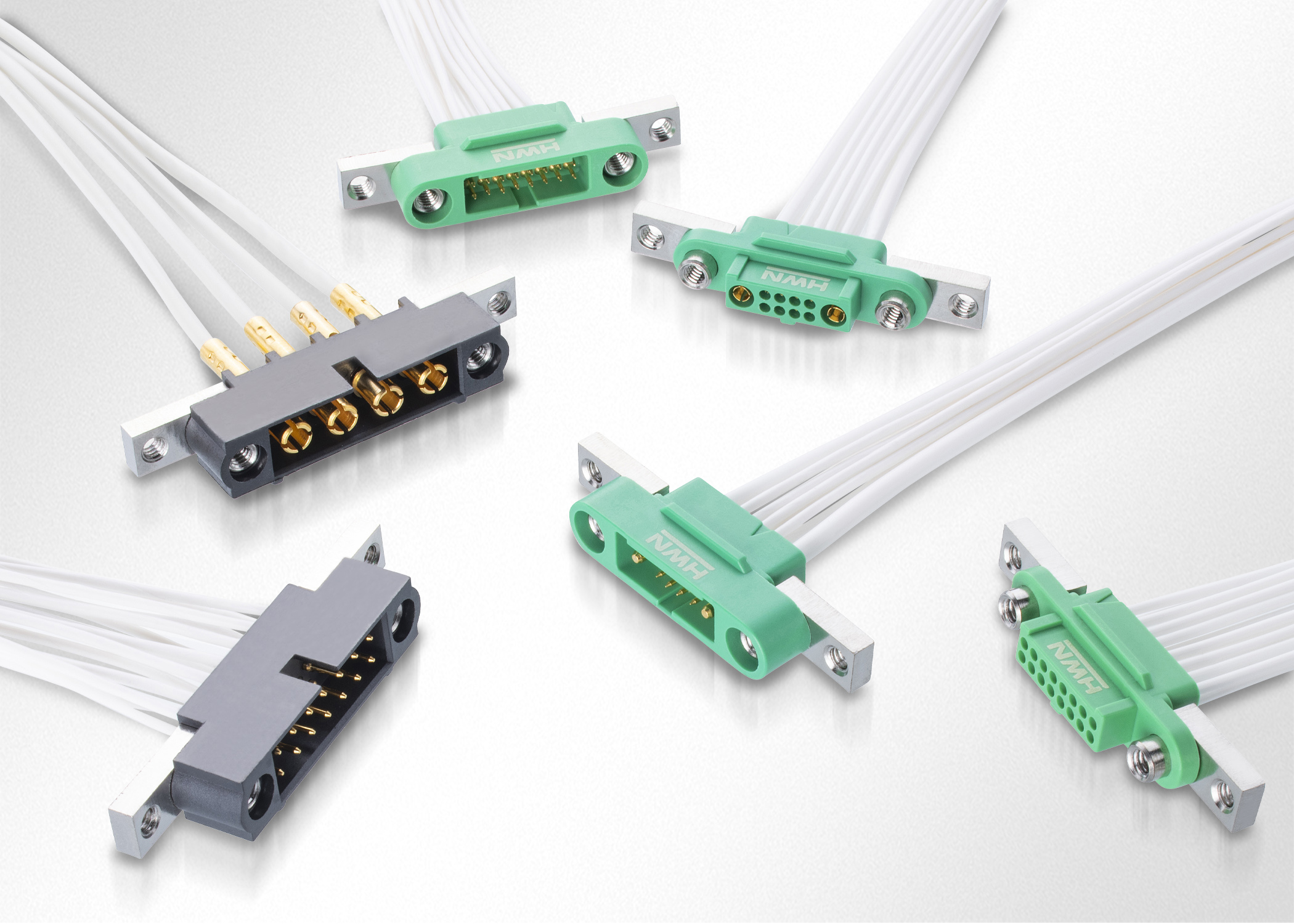

Versions of Harwin’s Datamate J-Tek and Datamate Mix-Tek (combining power and data pins) connector products will be available with rear panel mounting jackscrews. These will be fitted to male cable connector housings. The more compact Gecko-SL and Gecko-MT products with rear panel mounting are fitted to both male and female cable connector housings. For all these products, contact counts of up to 50 per connector are supported.

The new rear panel mount cable connectors utilise a proprietary fixing structure. As well as incorporating internal screw fixings for mating purposes, the connectors also feature extensions to each end. These allow a second hole to be accommodated for panel attachment. All of Harwin’s rear panel designs are compatible with the company’s existing mating cable connector portfolio. Because of this, there is provision to retrofit them into legacy deployments. It also means that no further design work is required to replace existing external cable harness.

“Connectors attached to a panel or enclosure help lower any strain placed on electrical connections inside the unit. This extends the working life of equipment and avoids repairs,” says Ryan Smart, NPI Product Manager at Harwin. “After consulting our customer base, it was clear that many preferred a rear panel mounting solution. Putting the connector on the inside of the enclosure gave them sleeker equipment modules and connectors less vulnerable to damage. Now we have both front and rear mounting for Datamate and Gecko, our customers can choose whichever option they need.”