The large number of sensors and actuators in industrial equipment or mainstream household devices is hard to ignore. Visual and touch interfaces are omnipresent on industrial equipment, as well as all kinds of sensors that tell exactly what is going on inside the machinery. A bit like the evolution in household printers, guiding you step by step whenever a sheet of paper gets stuck or an ink cartridge needs replacement. Nowadays, even an electrical toothbrush comes with OLED screen and Bluetooth connectivity. Imec internally reorganized and upgraded its activities on sensor and actuator technologies to better cater to the evolving needs of this growing industry. A shift towards higher TRL levels in combination with more pro-active developments on specific applications are amongst the strategies, as Paul Heremans, vice president sensors and energy technologies at imec, explains.

Market trends

The number of sensor and actuator devices in industrial and consumer devices has never been so high. The industrial-sensors market exceeded $20B in 2019, according to a report by Global Market Insights. The demand in sectors such as manufacturing, energy&power and healthcare will push global shipments of industrial sensors above three billion units by 2026. A staggering number, and at the same time only half of what is observed in the imaging industry. IC Insights estimates image-sensor shipments to surpass six billion units in 2020 already. Which might not come as a surprise knowing there’s an average of more than three cameras in each smartphone nowadays.

Key to back these immense growth numbers are the scalability of the sensor and actuator devices and their building blocks. Scalability in terms of ‘manufacturing capacity at acceptable cost’ and scalability often also in terms of ‘downscaling their form factor to fit into embedded or mobile devices’. Take for example a high-end infrared camera. Depending on the desired specs, its current price point can go up and around ten thousand euros. Which puts it within reach of only a limited number of application areas such as military and space. Once similar capabilities can be integrated at the fraction of the cost (and size), an explosion of new markets and use cases can happen in industries such as life sciences, security, instrumentation, agrofood… The current approach to use III-V materials and flip-chip assembly will not be sufficient to reach the necessary miniaturization and cost-efficient manufacturing goals. For this to happen, upscalable CMOS-based technology on 200 or 300mm wafers is an indispensable enabler.

Aside from these quantitative targets, the industry is also looking for new modalities and additional ways to integrate sensor and actuator solutions. For example, but not exclusively, to get certain applications within closer reach of a larger number of end users. A good example is Apple’s integration of a light-detection and ranging (LiDAR) scanner in the iPad Pro 11. The trends in mobile displays can be taken as an example to get an idea of the possibilities in a wide range of applications. OLED displays are becoming the dominant technology for mobile phones and watches. There is barely a need to further increase the resolution (~500ppi in the state of the art), but the trend is to make the display as large as the screen, i.e., to remove all visible bezels. As a consequence, the sensors that are integrated in the front screen need to disappear in the display: ambient light sensor, proximity sensor, selfie camera, fingerprint sensor, face recognition, heartbeat. Furthermore, we may expect in the future more sensors to find their way in the display, e.g. an integrated 5G antenna, or haptic feedback. And as the smartphone is becoming the prime personal assistant, there is a trend to integrate in particular more health-monitoring sensors, such as an oxygen saturation sensor, glucose sensor, analyzer for allergens, etc… And this is ‘just’ about smartphones. Similar scenario’s can be depicted for almost all other application areas as well.

Technology enablers

Imec’s focus is twofold: to enable miniaturization and to develop new sensor and actuator modalities; both by leveraging on the available semiconductor expertise. As for new modalities, the development of a short-wave-infrared

CMOS camera is a good example of a recent achievement. In 2019, imec demonstrated a camera-integrated solution allowing Si-based CMOS sensors to detect short-wave infrared wavelengths that are normally out of reach for them because of physical and optical laws. Scale-down was shown at IEDM 2020. Thanks to imec’s approach and expertise, such short-wave-infrared cameras can soon be made in high volumes and at much reduced cost compared to today.

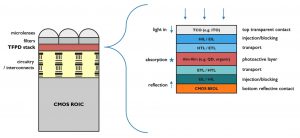

Figure 1: By processing a thin-film multilayer stack with photoactive layer sensitive in the

infrared range (right), on top of a Silicon readout circuitry (ROIC), imec created an IR-sensitive

CMOS imager (left) compatible with mass manufacturing.

Another example is imec’s work on photo-acoustic imaging. In photo-acoustic sensing, a light source sends radiation of a specific wavelength into a sample, where absorption causes thermal expansion. This results in sound waves that can be picked up by a sensitive microphone. Photo-acoustic systems have a benchtop-size today and have been shown to be extraordinarily sensitive. They for example allow to non-invasively measure blood-glucose levels – or the concentration of analytes in other contexts – with extreme precision. By using semiconductor technologies, imec aims to integrate ultra-sensitive microphones and light sources with high spectral purity onto a chip; and, as such, bring photo-acoustic sensing to the next level.

On a somewhat related topic, imec is also using acoustics, ultrasound in this case, for haptic-feedback systems. Haptic feedback is an emerging human-machine interface, in which a machine can ‘touch’ its operator by triggering mechanoreceptors in the human skin without physical contact. This adds a new dimension of ‘touchlessness’ to currently available user interfaces and can play a critical role in the low-touch economy which is expected to emerge post-COVID-19. At the heart of the first-generation of haptic-based interfaces are bulky piezoelectric ultrasound transducers, which are cumbersome in use, impede a very fine interaction and limit end-product integration possibilities. Imec’s ambition is to develop a dense array of one or more ultrasound transducers types in large area format to modulate the output power and precisely focus the ultrasound beam in mid-air at distances ranging from few centimeters to tens of centimeters.

Imec technology moves up the TRL ladder

As becomes apparent through these examples, compatibility with semiconductor manufacturing always inherently enables scalability, often goes hand in hand with miniaturization and often with improved performance as well. Looking at the traditional building blocks of an electrical system (processing, memory, connectivity, input/output), imec is world-leading in each of them and now reinforces its focus on the sensor and actuator technologies that enable the system input and output.

The new internal strategy builds on two main foundations. It is more proactive in the technology development for high-potential application areas and takes these selected technologies towards a higher technology-readiness level. Until now, imec was in its sensor and actuator developments mainly focusing on its underlying capabilities (e.g. ultra-low power electronics, thins-film technologies, imagers, microfluidics), and generic integration capabilities. In the new strategy, imec will keep strengthening its capabilities and – on top of that -be more proactive in developing prototypes and system demonstrators based on its own knowledge and insights of what these promising markets might need.

Two of those domains could certainly be life sciences and industrial equipment. For those, there are numerous potential applications for sensor and actuator technologies and they are close to imec’s application-oriented R&D divisions. In life sciences, one could think of all kinds of optical and acoustics-based system enhancements for diagnostics and surgery and leverage can be created via imec’s life-science technologies division. Also, the entire industry 4.0 vision relies on sensor and actuator enabled solutions and can internally build on imec’s unique ecosystem of equipment suppliers. But also other sectors will be investigated. For example, agrofood, the focus area of imec’s OnePlanet initiative, could benefit from e.g. integrating SWIR cameras on drones for crop monitoring or using ultrasound technology to monitor fruit ripening. And in waste management, short-wave infrared or other electromagnetic waves can be used to sort plastics that are difficult or impossible to distinguish in visible light. And as soon as imec’s sensor and actuator engine is oiled and running in these business-to-business sectors, it won’t shy away from consumer-electronics domains either.

Want to know more?

- Read the recent press release on imec’s miniaturized SWIR camera as presented at IEDM2020.

- Learn how imec brings photolithography into the domain of OLED manufacturing in the IDW2020 press release: Imec Applies Photolithography To Push Functionality and Reliability Barriers In OLED Display Manufacturing | imec (imec-int.com).

- Read all about imec’s SWIR-enabled CMOS camera in the imec magazine article “Make smartphones and autonomous vehicles see the impossible”.

Read the imec-magazine article and watch the video on “Haptic feedback: the next step in smart interfacing”.