Freiburg, October 6, 2016 – Micronas, a TDK group company, expands its Hall-effect sensor HAL 18xy family with the HAL 1860, a small, robust and cost-effective solution with output signal supervision capabilities. Several programmable output signal clamping levels extend error signaling capabilities to indicate various fault conditions like under/overvoltage, under/overflow of the signal path, or overcurrent. A one-pin programming interface enables simultaneous programming of several devices through the output pins. Other major sensor characteristics like magnetic field range, sensitivity, offset and temperature coefficients are programmable in a non-volatile memory.

“The small package and the protection functions of our new HAL 1860 sensor are perfectly suited for space constrained and harsh environments. The type of diagnostic and clamping used to enhance the signal integrity are usually found on higher-end devices. Furthermore, our customers will improve productivity thanks to our programming interface enabling the sensor performances to be optimized at the end of their production line. You clearly get more for less!“, says Matthieu Rezé, Product Marketing Manager at Micronas.

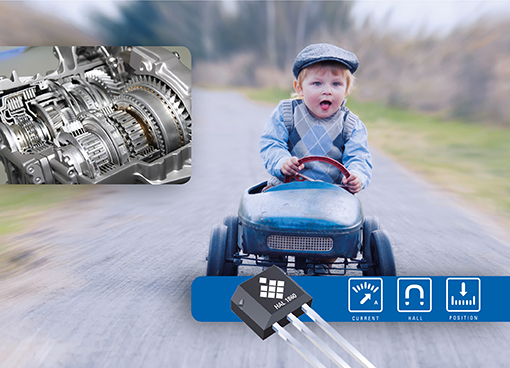

Thanks to the aforementioned benefits, the HAL 1860 is the optimal system solution to measure small angle (<90°) or linear displacement (few mm) in stringent applications. For example, it can be used as gear position detection sensor in dual clutch automatic transmission or steering torque sensor for industrial/recreational vehicles.

The HAL 1860 is qualified according to AEC-Q100 and is packaged in an industry standard 3-pin TO92-UA, lead (Pb) free, with matte tin leadframe plating. It comes with two lead forming configurations: an inline version with 1.27 mm pin-to-pin spacing or alternatively a spread version with 2.54 mm pin-to-pin spacing, better suited for welding process.

Samples are available now. Start of production is planned for early 2017.