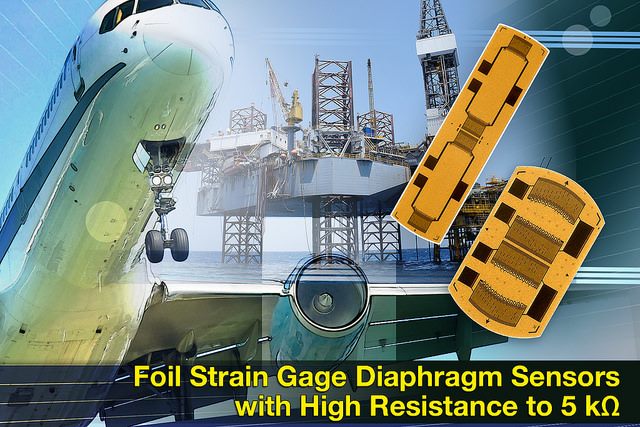

MALVERN, Pa. — Oct. 27, 2015 — Micro-Measurements®, a Vishay Precision Group, Inc. (VPG) brand, has expanded its line of linear and circular diaphragm sensors with the introduction of smaller, higher-resistance patterns to serve a wider variety of pressure measurement applications.

Strain gage manufacturers have produced diaphragm gages for use in pressure transducers for over 40 years. The devices’ unique design allows precise placement of the sensing grids on the diaphragm surface, taking full advantage of the steep strain gradients characteristic to these designs. Built on Advanced Sensors technology, Micro-Measurements’ new generation of diaphragm strain gages offers a number of unique benefits, including improved grid-to-grid temperature matching, a broad selection of patterns, high resistances to 5 kΩ with tight tolerance of ±0.2% per grid, and short grid lengths (down to 0.5 mm). The shorter grids result in a higher output because the active portion of the grid is better matched to the peak strain areas on the diaphragm.

“Using traditional manufacturing techniques, strain gage manufacturers needed as much area as possible to achieve resistances above 350 Ω,” said Matt Saas, Micro-Measurements senior applications engineer. “The steep strain gradients limited the grid length, so the outer grid width had to be fanned out radially to take advantage of the entire strain field. This caused increased pattern complexity and resulted in high manufacturing costs. With our Advanced Sensors technology, smaller grid designs are possible with higher resistances and outputs.”

Micro-Measurements’ Advanced Sensors strain gages are available in a variety of sizes and tab configurations, and they can be installed using automated pick-and-place technologies.

Samples and production quantities of the diaphragm sensors are available now, with lead times of six weeks for prototype samples and 12 weeks for standard orders.

Further information about Micro-Measurements strain gages and technical support is available at www.micro-measurements.com. Follow Micro-Measurements at www.strainblog.com ortwitter.com/strain_gage.