Occasion honoured by Royal presence – a validation of UK excellence

Harwin, the leading hi-rel connector and SMT board hardware manufacturer, has officially opened its new manufacturing centre in Portsmouth, increasing floor space by 33%, which is dedicated to increased automation and R&D facilities. The new £3M, 3000m² building was opened by HRH Prince Michael of Kent. Also present were: David Fuller, Lord Mayor of Portsmouth; Tom Floyd, High Sheriff of Hampshire; Michael Campbell, Deputy Lord Lieutenant of Hampshire; local Portsmouth North MP Penny Mordaunt, the Minister of State for the Armed Forces; plus representatives of local educational establishments and technology partners.

Committed to High Quality

Speaking at the event, Damon de Laszlo, Harwin’s Chairman was eager to stress the importance of the new facility within the company’s business philosophy. “We are committed to high quality manufacturing in the UK”, he explained, “and that means embracing Industry 4.0 smart factory practices, investing in the latest equipment, designing products for automated assembly, and empowering and training our flexible workforce.”

He continued: “The success we have experienced in recent years meant that we had simply outgrown our existing facilities. So to meet our growth plans, we had to expand. At the same time, we are working on developing our operations using Big Data methodologies – from a customer ordering perspective as well as manufacturing data – so we expect significant productivity gains to be made along with the increase in capacity.”

Investment in Equipment and People

Part of Harwin’s company’s philosophy is to keep all key manufacturing process – stamping, plating, moulding, turning, assembly and tool-making – in-house in order to ensure quality and support new product innovation. The company implements a strict policy of replacing its plant and equipment on a 5-year cycle, and is continually developing automated processes to remain competitive and to keep quality at the highest levels. Harwin also invests in its people and runs an approved apprenticeship scheme in partnership with local educational establishments – through which several senior members of the current management team have progressed.

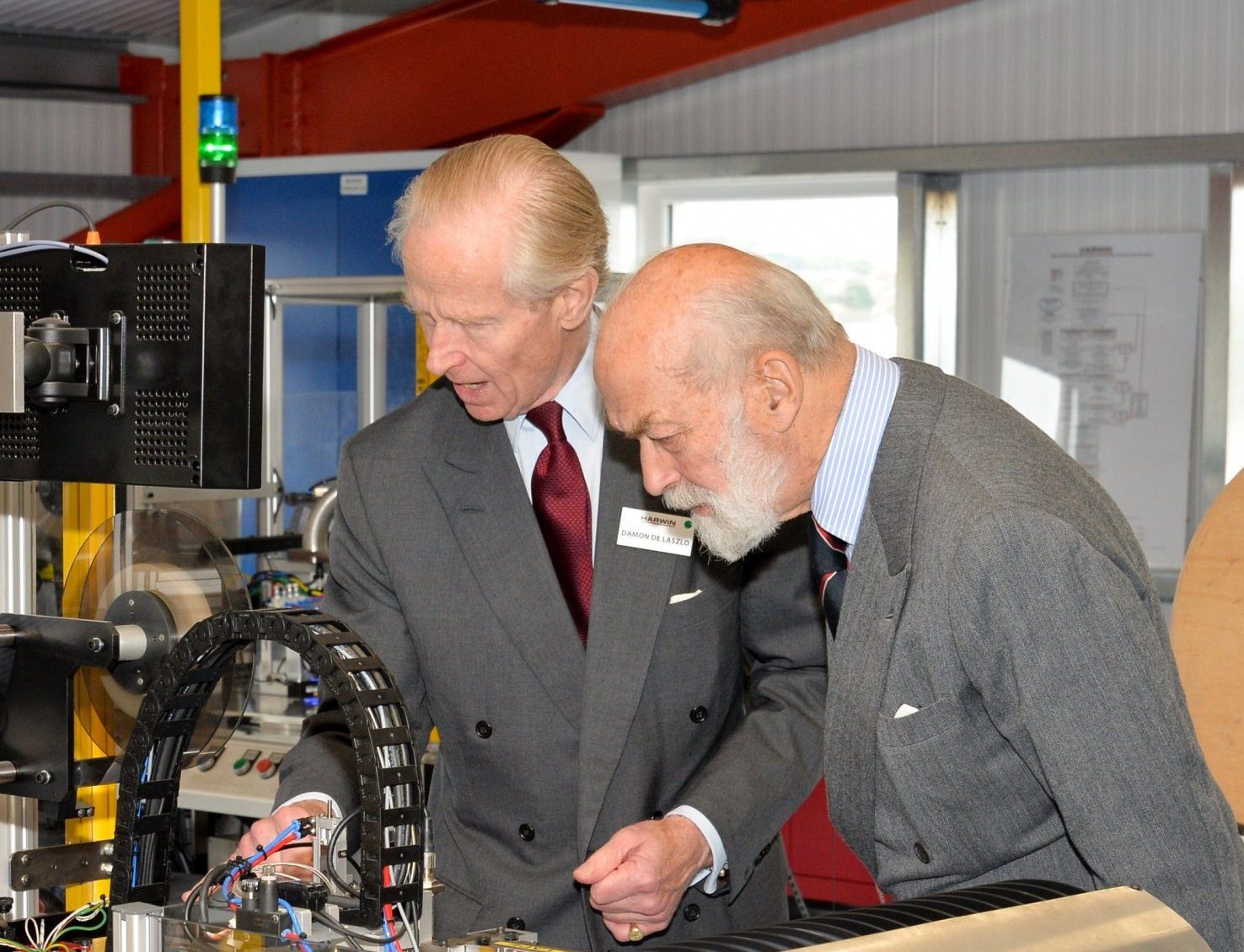

[Upper] HRH Prince Michael tours new automation area with Damon de Laszlo,

and [Lower] meets the current Harwin apprentices