Low energy consumption has replaced performance as the foremost challenge in electronic design. Performance is important, but it must now accede to the energy capacity of batteries and even the minimal output of energy harvesters. Performance at all costs no longer works; energy consumption is now the dominant requirement. While reducing energy consumption is critically important throughout the electronics industry, the question is: how should that goal be achieved? Ambiq Micro’s approach moves beyond the incremental improvements that other semiconductor companies have taken and makes revolutionary advances through a unique approach to the problem: sub-threshold circuit design.

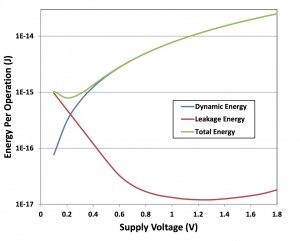

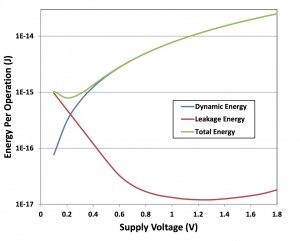

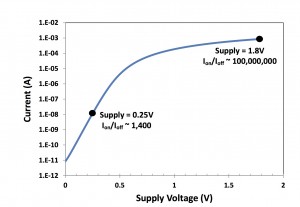

Energy is consumed in two fundamental ways: as leakage, when a circuit’s state isn’t changing, and dynamically as internal nodes are charged up and down. For realistic circuits in operation, dynamic power dominates – especially for the higher power supply voltages used in most designs today (see Figure 1 below).

Figure 1 – Dynamic current dominates with higher operating voltage

Because dynamic energy varies as the square of the operating voltage, that voltage becomes the biggest lever for reducing dynamic energy consumption (while also having a tangible, but less dramatic, impact on leakage). For example, when compared to a typical circuit operating at 1.8V, a “near-threshold”

Energy Per Operation (J)

circuit operating at 0.5V can achieve up to a 13X improvement in dynamic energy. An even more aggressive “sub-threshold” circuit operating at 0.3V can achieve up to a 36X improvement!

Traditional digital designs use the transistor state – “on” or “off” – as a critical concept for implementing logic. Analog designs likewise assume that a transistor is “on” to some controlled degree, using it for amplification. But sub-threshold operation means that none of the voltages in the chip rise above the threshold voltage (Vth), so the transistors never turn on. Even a logic “high” voltage keeps the transistors “off.” This means that completely new design approaches are required.

This whitepaper examines the challenges of sub-threshold design, looking in particular at what’s required to overcome the differences from traditional super-threshold design. These considerations drove the development and commercialization of Ambiq’s patented Sub-threshold Power Optimized Technology (SPOTTM) platform, which Ambiq uses to build reliable, robust circuits that consume dramatically less energy on a cost-effective, mainstream manufacturing process.

Sub-threshold was proven decades ago

Sub-threshold design isn’t a new concept. As far back as the 1970s, Swiss watchmakers noticed the potential of operating select transistors in the sub-threshold regime. The idea was picked up for pacemakers and RFID tags, but never saw much acceptance beyond that.

After a lull that lasted a couple of decades, the topic regained some academic status in the late 1990s and early 2000s. By that time, the upcoming primacy of energy consumption was evident, and research started into ways that commercial circuit designers could reduce energy consumption. Sub-threshold design techniques were among those ideas.

The founders of Ambiq were part of that academic revival, working at the University of Michigan to develop the technology more thoroughly. That effort was spun out so that it could be fully commercialized. Ambiq is the only company utilizing sub-threshold design as a primary approach to reducing energy consumption.

It would be obvious to ask why, if this technology was developed in the 70s, it never caught on. One might even suspect that some flaw might have been uncovered that kept sub-threshold out of the mainstream. It begs the question, “If this is so easy, why isn’t everyone doing it?”

The answer to that question is, “Because it’s not so easy.” There is no fatal flaw, but the transition from super-threshold techniques has not been trivial. Ambiq’s founding team started their work at Michigan in 2004 and worked until 2010 to make the technology usable on a broad, commercial scale.

One might also ask what’s changed since the 70s, when the first commercial sub-threshold devices were created. The difference is scale: Designs of the past used a few critical sub-threshold transistors – on the order of 10. At that level, each transistor can be optimized by hand. By contrast, Ambiq creates entire chips that primarily use sub-threshold transistors. That makes hand-crafting completely impractical. Designing millions of such transistors is possible only by using standard design tools and flows – preferably the same as those that have been used for super-threshold design. This is the work that Ambiq has done to commercialize sub-threshold circuits.

The challenges of modern sub-threshold

Adapting the standard super-threshold flows and infrastructure for sub-threshold design presents numerous detailed challenges. These start with the very transistors themselves.

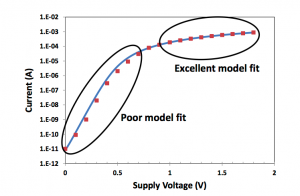

- Poor transistor models

The transistor model forms the basis of everything in an integrated circuit design. All of the simulations, all of the abstractions and automation, the very process of design closure: they all rely on an accurate transistor model. Most transistor modeling has focused on the “on” characteristics of the device, with little attention given to “off.” The entire region between 0 V and Vth typically does not get modelled as accurately, and so existing models are inadequate for sub-threshold design, as shown in Figure 2.

Figure 2 – Transistors haven’t been well modeled below threshold

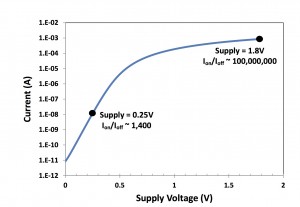

Logic swings and noise

The output response of a transistor in the sub-threshold regime is subtle; detecting it requires great sensitivity. Currents change exponentially in response to changing voltages, but they’re exceedingly small currents. In addition, the ratio of “on” to “off” current is on the order of 1000, orders of magnitude less than what super-threshold designs experience (see Figure 3). As can be expected, external noise can much more easily interfere with clean operation.

- Sensitivity to operating conditions

Sub-threshold designs are also far more susceptible to process and environmental variation than are super-threshold designs. For example, the current in a slow process corner can be 10-100 times less than that for a nominal process. Given that the on/off current ratio (above) is only on the order of a thousand, this cannot be ignored.

Figure 3 – The on/off current ratio is orders of magnitude smaller in the sub-threshold regime

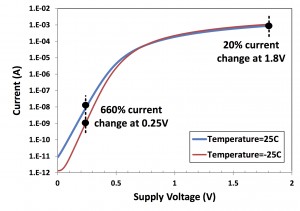

Variations in temperature provide a good example of how environmental conditions create a challenge for the designer. Vth depends on temperature, and Ion depends exponentially on Vth (as shown in Figure 4 below). As a result, the “off” current at elevated temperature is similar in value to the “on” current at reduced temperature for an uncompensated circuit. Sub-threshold circuit design therefore requires extra effort to ensure that the circuits will operate as expected under all specified operating conditions.

- Logistical challenges

Much of the manufacturing flow is based upon assumptions that are reasonable for super-threshold designs but break down for sub-threshold designs. One obvious such challenge can be found in the testers used to validate the silicon during production. The parametric measurement units (PMUs) that test voltages and currents are designed to measure microamps, not nano- or picoamps.

Figure 4 – Sub-threshold circuits are exponentially sensitive to temperature

Even something as straightforward as device characterization has to be rethought simply because of the sensitivities that sub-threshold circuits have that super-threshold circuits don’t have. Typical characterization flows may not be thorough enough to prove that the circuits operate properly under all conceivable conditions.

The fundamental nature of these challenges, combined with the fact that few engineers are skilled in dealing with sub-threshold issues, explains the challenge of commercializing sub-threshold-based circuits.

Current (A)

Ambiq’s solutions

The development of Ambiq’s SPOT technology, which addresses all of these challenges, has been a multi-year effort involving multi-faceted solutions, starting with a better understanding of the transistors themselves.

Ambiq recharacterized selected transistors from mainstream processes in the sub-threshold regime. It was important to start with standard low-power transistors, since the goal was to build these circuits on standard processes to keep costs down. This recharacterization effort required building numerous devices in order to capture the effects of variation and to better understand the process and environmental corners, thereby enabling the design of robust circuits.

Once the transistors were better understood, cells and circuits had to be modified to operate with sub- threshold voltages. Before doing this, the cell library was carefully surveyed and pared down. Commercial libraries tend to undergo cell proliferation as variants of standard circuits are created for different circumstances. So the first job was to select which cells from the library were to be adapted to sub-threshold operation. Once the critical cells were identified, they were then redesigned as sub- threshold circuits.

There are two goals behind these circuit design efforts. One is to manage the extreme sensitivity to changes in threshold voltage and operating condition, and the other is to optimize operation for minimal energy consumption. There are a number of techniques that can be employed in both cases, and all of them are important components of the SPOT platform.

Analog circuits, meanwhile, have required additional work. While existing super-threshold digital cells could often be modified for sub-threshold use, analog circuits typically required a fresh start. A disproportionate effort was put into creating and verifying analog circuits that were substantially different from their super-threshold versions.

None of the approaches taken is enough on its own, and none is appropriate in all cases. Ambiq’s circuits are successful because they pick and choose from amongst different techniques, applying some or all of them in different parts of the integrated circuit. There is no magic formula that dictates what to use where; it takes solid engineering and good design to pull together the right combination that provides the required performance with the lowest energy, while at the same time paying attention to chip area and cost.

This need to use different techniques even applies to the type of transistor and the regime within which it will operate. In some cases, super-threshold transistors can make sense. Since super-threshold circuits are simpler, using them where they don’t affect energy consumption can be beneficial.

A good example of this is the non-volatile memory (NVM) that can be used to store settings or calibration values while the device is powered down. At power-up, those values need to be loaded into active registers. Those registers will likely use sub-threshold transistors, but the NVM and the transfer

circuits can be designed with standard super-threshold transistors since they operate only at power-up and then are shut down.

The general approach Ambiq uses is to start with sub-threshold transistors as the default approach, and then to review to see if any parts of the circuit can be operated at super-threshold levels without impacting energy consumption. Super-threshold design is simply easier, so it’s preferred if power permits. In most cases, however, power does not permit it; super-threshold circuits are the exception.

There are also occasions when critical sub-threshold circuits don’t achieve the required performance. In those select cases, the operating voltage for that island may be raised into the near-threshold region. To date, no circuits have had to go to super-threshold levels to get to the required performance.

So the overall strategy is to use sub-threshold circuits throughout by default, use super-threshold in those few cases where it’s possible, and use near-threshold in those few cases where required for speed or bandwidth.

Ambiq Micro is successful with its sub-threshold circuits because it leverages all of these techniques as needed; this diversity of options is a critical characteristic of the SPOT platform. In particular, Ambiq’s circuits involve the extensive use of dynamic, adaptive strategies that keep the circuits operating optimally even as conditions change. Sub-threshold design can be frustrating, with solutions to one problem creating new problems in whack-a-mole fashion. To some extent, it’s simply hard work done by engineers skilled in sub-, near-, and super-threshold design that has allowed Ambiq to be the first company to design circuits that overwhelmingly rely on sub-threshold circuits.

Design and logistics impact

A great deal of effort has gone into ensuring that Ambiq’s sub-threshold circuits leverage existing established flows wherever possible. Custom processes might make life easier, but they’re not required, and Ambiq’s focus is on using what is already known to work well.

The design flow was impacted based on the number of custom cell libraries and the sheer number of corners to be verified, given the various design techniques available to manage the circuit sensitivities. These design flow challenges are being encountered in the super-threshold world at the 28-nm process nodes, so solutions exist. It’s just that Ambiq has leveraged those solutions at more widely available process nodes. Importantly, Ambiq’s SPOT technology can also be scaled to lower geometry processes for even more energy savings as those nodes become more mainstream.

Testing challenges such as the need to measure low currents were addressed by creating complex custom probe cards and on-chip test circuitry. Those cards include specific custom current-measuring circuits that handle the measurements that the tester itself cannot manage.

Finally, the characterization flow had to be much more thorough than what would typically be done for a super-threshold design. It necessitated more detailed measurement under many more conditions and combinations of conditions than would typically be done. The impact of this is greater confidence in the robustness of the product.

In general, no step of the design and manufacturing flow has escaped scrutiny. Where elements of the standard flows have fallen short, Ambiq has modified them to ensure that the resulting product is indistinguishable from something built using super-threshold techniques – with the exception of energy consumption.

Proven reliability

Creating novel circuits means not only building something that works now, but also ensuring that the circuits will operate correctly for the life of the chip. For a system designer, reliability expectations will be the same regardless of the particular circuit techniques involved.

For that reason, sub-threshold circuits built on Ambiq’s unique SPOT platform have been subjected to the usual battery of reliability tests, involving multiple lots exposed to extreme conditions over extended time periods as well as other standard tests such as electrostatic discharge (ESD). The circuits have proven themselves to be robust, and reliability reports detailing the results of these tests are available.

Conclusions

The use of sub-threshold techniques can be a powerful way to create circuits that consume dramatically less energy than those built using standard design practices. It’s a fact that sub-threshold design is difficult. But, given the right experience and diligence, it is a solvable problem, and one that Ambiq continues to solve via their patented SPOT technology.

The result of these efforts are circuits that provide the same functions as more traditional ones using a fraction of the energy. There is no compromise in performance, robustness, or reliability; Ambiq’s chips can operate alongside their traditional counterparts with no externally-visible difference – except for the amount of energy required to drive them. They can provide important energy savings to designers building energy-efficient systems.

Because of the fundamental nature of these innovations, sub-threshold design techniques can be applied to virtually any type of IC device. For example, Ambiq demonstrated the viability of this innovative approach with the introduction of the world’s lowest power real-time clock (RTC) in 2013. The upcoming release of the world’s lowest power 32-bit ARM-based microcontroller (MCU) further demonstrates the viability of extending these techniques to a completely different platform. Ambiq Micro is committed to expanding the SPOT Platform — and to giving batteries a better life.