VTT Technical Research Centre of Finland Ltd and Hydroline Oy have joined forces to develop networked, intelligent next-generation hydraulic cylinders. The project enables a transition from a product-centric business model to a new service-based business model to boost competitiveness.

Digitalisation is propelling product development in the manufacturing industry forward at speed. This allows new product and service concepts to be developed faster and more and more profitably.

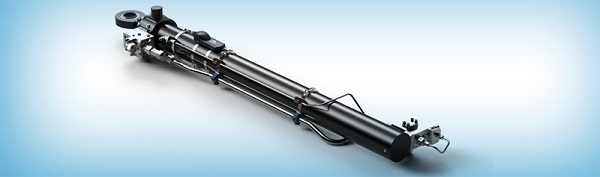

Finland’s leading hydraulic cylinder manufacturer Hydroline and VTT have joined forces to turn the company’s products into services. Hydraulic cylinders are used extensively in heavy machinery and industrial applications thanks to their excellent power density, reliability and user-friendliness.

The aim of the new four-year Tekes-funded project launched in the spring is to build a digital platform for the company to use in life-cycle management and in-service maintenance. Digitalisation enables new business development and shifting the focus from products to selling services.

“VTT’s broad competence and ability to pool together the expertise needed for the project make them almost a one-stop shop for us”, explains Manu Leinonen, Vice President, Design and R&D from Hydroline.

The project takes advantage of the latest artificial intelligence and machine learning technologies. VTT’s technological know-how enables concepts to be implemented and introduced into the company’s product portfolio quickly.

The project follows on from a previous EU-funded joint project of VTT and Hydroline, which culminated in Hydroline launching a new predictive maintenance system for hydraulic cylinders in the spring. The usage data processed in the cloud and mobile based system ensure that all the hydraulic cylinders of an excavator, for example, are serviced before an unexpected fault occurs, which saves time and money without needing to take an expensive machine out of service.

“Hydroline’s product innovations and joint projects are an excellent example of VTT’s role in transforming the SME sector in Finland. Cooperation with VTT has helped the company to modernise its products and business and therefore enabled the company to become a service provider within its network”, explains Erja Turunen, Executive Vice President, Smart Industry and Energy Systems from VTT.

“The digitalisation of products and product and production processes as well as the associated data analysis, machine learning and hybrid modelling technologies bring new opportunities for the predictive maintenance and optimised use of assets and therefore savings”, explains Project Manager Pekka Isto from VTT’s Production and Machine Systems team.