Our world is filled with intelligent (smart) products and technology to make our lives more efficient, convenient, connected and informed. We come into contact with these smart devices every day. More and more cities are employing smart traffic lights that adjust to real-time traffic conditions. Smart street lights and office lighting dim or turn off when no one is around to conserve energy. High efficiency top load washers determine the water level for each load based on the weight of clothing in each load. New smart automobiles respond to adverse conditions and feature parking assist. Cell phones respond not only to your touch but also the force of your touch. Many of these systems incorporate multiple analog sensors that are used to detect pressure, temperature, force, position, light, flow, sound, speed, heat, etc.

Between the analog sensor and digital signal processing lies an important electronic interface that conditions the electrical signal to ensure it lies within the range of the downstream ADC (analog-to-digital converter). This signal conditioning or sensor interface block is highlighted in Figure 1. Analog sensors produce an electrical signal that is usually very small and surrounded by noise. In many cases, no two sensors are alike, each sensor carries its own unique noise signature, introduces its own offset into the signal path and requires a different gain to meet the requirements of the downstream ADC. Calibrating the system, differentiating signal from noise and amplifying it are crucial to end system performance.

Today’s system designer is faced with choosing between developing a discrete sensor conditioning function or making use of a more integrated sensor interface analog front end (AFE). Unfortunately, there is never a clear choice for all applications. Footprint, ease-of-use, flexibility, performance, price, and functionality are all things to consider. This article will describe some benefits and short-comings of each.

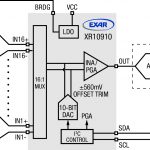

- Figure 2: XR10910 as Hall Effect Sensor Interface AFE

- Figure 1: The Signal Conditioning Block conditions analog sensor signals for use by downstream MCUs or FPGAs with integrated ADCs

Footprint Comparison

If real-estate is a concern, then a more integrated solution is usually more desirable. Take for example a system that uses 16 Hall Effect sensors to monitor current in a solar panel application. The XR10910, a 16:1 sensor interface AFE has a 6mm x 6mm footprint and integrates a 16:1 differential multiplexor, a programmable gain instrumentation amplifier (PGA), a 10-bit offset correction DAC (digital-to-analog converter) and an LDO (Low-dropout regulator). As shown in Figure 2.

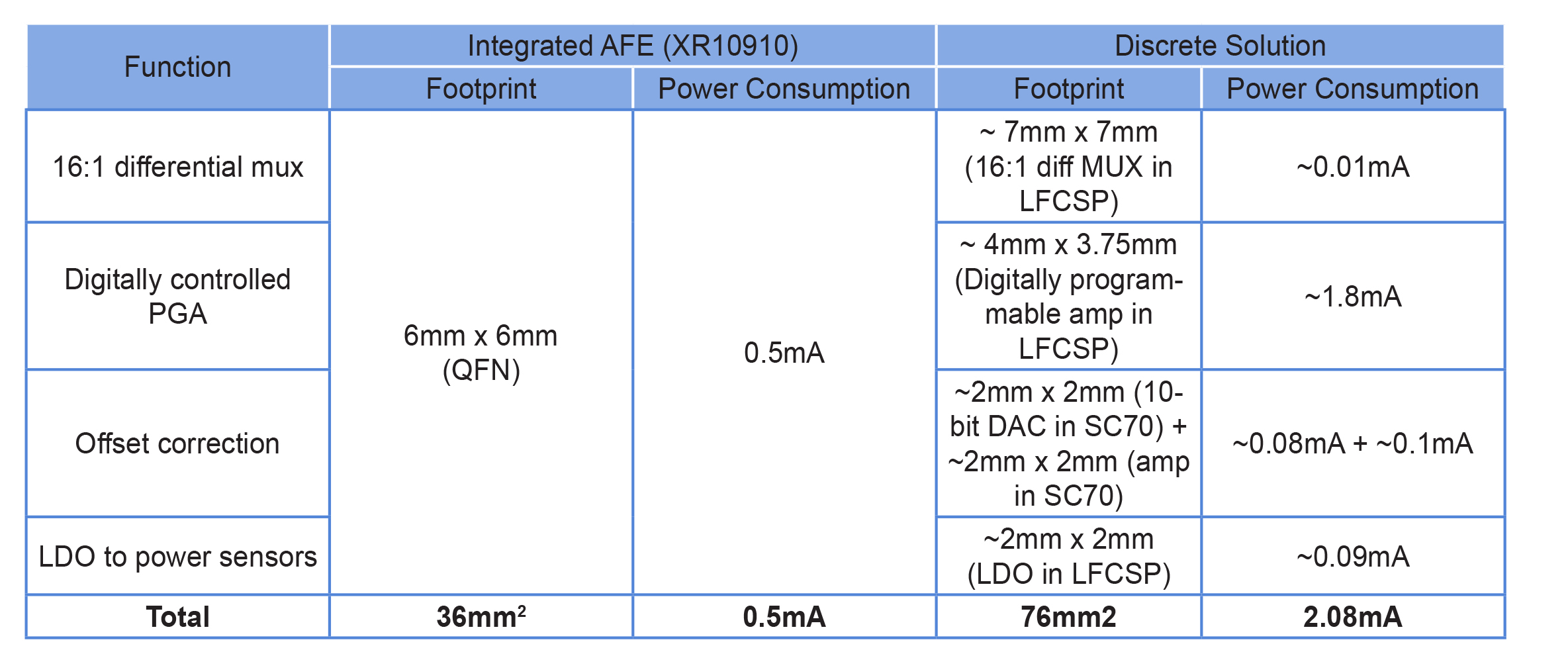

The XR10910 AFE allows each Hall Effect Sensor to have a unique amplification and offset correction path. This function can be handled discretely but with approximately two times the footprint and four times the power consumption, refer to the example shown in the table below. There are many ways to implement a discrete solution for this function, the below table takes only one into account. In most cases, an AFE will have a total footprint advantage over its discrete counterpart.

Performance Comparison

When it comes to performance, the end application plays a crucial role when deciding between a discrete and a more integrated solution. There are literally thousands of precision amplifiers on the market with varying price/performance tradeoffs. And only a handful of integrated AFEs. When manufacturers develop an AFE, they typically have set applications in mind which dictate the overall performance specifications of the device. The XR10910 mentioned above offers 1mV maximum offset voltage, 2µVpp noise, and a gain range of 2V/V to 760V/V. Although this may be adequate for some applications it most certainly will not fit every sensor interface requirement out there. If performance is the designers’ top priority and you cannot find an AFE on the market designed specifically for your application, then a discrete solution will usually be the preferred method because the designer can hand-pick the components to best fit his/her needs. Ultimately fine tuning the sensor conditioning block.

AFEs on the market today offer different levels of integration. Some include an ADC or processing power, while others like the XR10910 do not. Most sensor interface AFEs on the market are very application specific, thus their performance feature set and functional blocks are extremely useful when used in the target application. For example, there are several AFEs on the market today that were designed for medical instrumentation applications and integrate 16-bit or 24-bit delta-sigma ADCs, PGAs and a host of features designed to reduce size, power, and time to market if you happen to be designing an ECG (electrocardiogram) or other medical diagnostic equipment. But if you are a designer with the challenge of conditioning multiple Hall Effect sensors, as described above, this highly integrated AFE is not the answer. Something with less integration and more flexibility is needed.

Conclusion

Sensor interface AFEs tend to offer faster time to market, higher ease of use, smaller footprint and in many cases lower power. But many are extremely specialized for certain applications and are not able to support multiple sensors or multiple types of sensors. Discrete solutions tend to be more flexible and can be fine-tuned to each specific application, but they require analog design prowess, more real-estate, more power, and tend to lack many automated features like auto calibration to correct for sensor drift.

The XR10910 feature set truly unique in the market, filling the gap between less feature rich discrete solutions and single-chip sensor interface AFEs that include processing power. Consuming only 457µA supply current and only 36mm2 of real-estate, the XR10910 offers the industry’s smallest, lowest power interface for 16 analog sensors. The XR10910 will be the first in a growing family of easy-to-use sensor interface products from Exar. Smaller channel count versions are on the horizon as well as versions that offer digital outputs.

Sensors enable the smart products and technology we use every day. Sensor conditioning products like the XR10910 will continue to play a key role in how these sensors interface with our ever growing digital world. Designers will continue to weigh the benefits of integrated AFEs versus discrete solutions and semiconductor manufacturers will continue to expand the AFEs offered in an effort to supply AFEs to a broader market space.