Implementing wireless connectivity through pre-certified wireless modules could represent the simplest solution to joining the Industrial Internet of Things.

Control, particularly when implemented in a programmable or ‘adaptive’ way, lies at the heart of automation; nowhere are the benefits of automation more apparent than in the industrialised world. Feedback is a fundamental part of control and bringing these two elements together is a concept upon which embedded electronics is based.

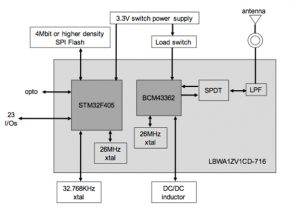

Figure 1: Block diagram of Murata Electronics’ LBWA1ZV1CD-716 module

As every engineer will confirm, feedback loops are essential to control; being able to quantitatively measure an output in a closed-loop as a result of changing input(s) underpins control in many applications. Within electromechanical applications, sensors form an important element in feedback and control, and analysis of the data they generate is fuelling an evolutionary step in industrial automation.

The benefits of data analysis in financial sectors is nothing new, but the fact that the analysis of industrial data can lead to significant productivity gains in all its sectors is now driving the rapid evolution of the Industrial Internet of Things (IIoT).

Figure 2: The WGM110A1MV1 Wizard Gecko

Building an ecosystem

Even as a subset of the much larger Internet of Things (or Internet of Everything, as it is also known) the IIoT still represents a massive opportunity; a market that is expected to be worth trillions of dollars within a couple of decades. While it evolves, its implementation is still open to interpretation and so offers companies of any size a chance to be a part of it. Anything that can deliver productivity gains through harnessing the power of the IIoT will be attractive to companies where margins are closely monitored.

In reality, fully exploiting an IIoT strategy requires much more than just using a sensor to measure the wear on a bearing or the flow of a fluid. It will require an ecosystem of hardware, software and services that, when brought together, will create a closed loop able to provide significant insights into industrial processes. This new landscape is likely to bring small, agile companies into close contact with larger incumbents, creating collaborations that will become commonplace thanks to the IIoT.

Figure 3: Block diagram of the ENW-89847A1KF PAN1760 from Panasonic

An IIoT framework will comprise many elements; from gathering data and storing or transferring that data to a server, to its analyses and the formulation of results, and ultimately acting on those results. The companies that can most benefit from the IIoT aren’t necessarily best placed to implement such a framework; it will instead fall to providers looking to bring the value of the IIoT to a wide range of customers. This is already in evidence as some companies reposition themselves to provide all or part of an IIoT framework. Electric Imp is one example, it now offers a Connectivity Platform comprising hardware (or ‘nodes’), software (including an operating system), cloud-based services and management tools. Some of its customers are already using this platform to gather real-time data across a number of industries including commercial refrigeration, HVAC systems and manufacturing equipment.

Figure 4: The ERIC9-FCC module

Wireless Connectivity Provides the Feedback

While sensors provide the ability to measure almost any real-world parameter, it is connectivity that provides the feedback to an IIoT framework. Connecting industrial equipment that is often large, in challenging environments or even constantly moving is difficult. While there are many wire-based approaches to this, such as CAN, Industrial Ethernet or RS232/422 as an example, they all exhibit the same drawback of needing a physical connection. In a growing number of applications, wireless connectivity has been proven to offer significant advantages, not least the flexibility of having no physical connection. Most wireless protocols have been conceived to offer security and robustness, and are capable of operating in almost any environment. With volumes driven by the consumer sector, the hardware needed to implement a wireless connection is now available at a compellingly low price point, enabling module manufacturers to compete with the cost of wire-based connectivity while offering all of the advantages inherent with a wireless solution.

As well as a turn-key platform, Electric Imp also provides the elements of an IIoT solution, including a Wi-Fi module developed to connect IoT nodes to its cloud service. The LBWA1ZV1CD-716 smart module is brought to market by Murata Electronics and integrates a Wi-Fi connectivity device from Broadcom with a powerful ARM Cortex-M4 based microcontroller from STMicroelectronics.

Measuring just 10mm by 7.9mm by 1.25mm, the smart module also offers 23 I/Os that can be configured as analogue inputs/outputs, SPI, UART, I2C or general purpose digital I/O. The flexibility of the module’s I/O would allow it to be implemented as an IIoT node with minimal configuration, as it is able to host an application and connect directly to the many sensors now equipped with I2C interfaces, for example.

The ability to provide built-in access to its cloud-based services makes Electric Imp a compelling option when adopting an IIoT strategy, however some applications may require a more open approach, by offering the ability to connect to a different network or service provider. In this case it may be necessary to develop more of the middleware needed to interface to a backend, fortunately module developers appreciate this and are now providing modules with Software Development Kits (SDKs), such as the WGM110A1MV1 Wizard Gecko from Silicon Labs.

The module is based on an ARM Cortex-M3 based microcontroller and a Wi-Fi chipset, and as such is able to run IoT applications in a standalone mode. However, for more complex applications, it is also able to run alongside a host (typically more powerful) processor, interfacing through either a UART, SPI or USB interface. In this mode, the module is controlled by the host using Silicon Lab’s high-level API, written in C and intended to run on the host processor alongside the IoT application.

From W-LAN to PAN

While Wi-Fi is positioned to provide a wireless alternative to Ethernet/LAN connectivity, the technology behind Personal Area Networks, or PANs, is also making its way into the industrial sector. Bluetooth, and now Bluetooth 4.0 (known as Bluetooth Smart or Low Energy, also referred to simply as BLE) provides a standard solution for establishing peer-to-peer wireless connectivity or ad hoc networks over shorter distances. This is particularly suitable for applications where data is collected periodically using a handheld terminal, for example. The ENW-89847A1KF PAN1760 from Panasonic is a BLE Smart Module based on the TC35667 from Toshiba. Measuring just 15.6mm by 8.7mm, and 1.8mm high, it provides a pre-certified solution to adding Bluetooth connectivity to a new or existing industrial application.

If wireless connectivity is being fitted retrospectively to an existing installation, as may be the case with many industrial applications, then it may be more advantageous to use a dedicated module that can be controlled using simple instructions from an existing microcontroller or processor. In this scenario, porting or redeveloping the entire application may not be necessary, it may even be possible to replace an existing wire-based connection with a wireless module with the minimum of design effort.

A good solution in this case may be the RN4020-V/RM120 Bluetooth module from Microchip Technologies. This module supports a number of Bluetooth services and is controlled using simple ASCII-based commands sent via the host processor.

Sub-GHz Solution

Operating in the 2.4GHz frequency range of the ISM (Industrial, Scientific and Medical) licence-free band, modules based on both Wi-Fi and Bluetooth offer simple access to wireless connectivity, making it simple to design-in or add-on to equipment operating in an industrial environment. However, sometimes the range needed may extend beyond that offered by PAN and W-LAN technologies, while the bandwidth required could still be relatively modest (a few hundred bytes of data on an infrequent basis). In these applications, a wireless solution operating in the sub-1GHz band might be more applicable.

The ERIC9-FCC module is part of the ‘easy Radio Intelligent Controller ‘ (eRIC) range from LPRS. It operates in the 868MHz range for use in the UK and Europe, or the 915MHz range for use in the USA and Canada, and is also pre-certified to ETSI (Europe) and FCC (USA) requirements. Instead of using an IEEE protocol, LPRS has developed its own easyRadio protocol, which comes embedded in the module along with the easyRadio operating system which abstracts away the complexity of running a wireless connection, leaving the end user with the simpler task of accessing the functionality using predefined functions. The surface-mount device measures just 15mm by 20mm by 2.2mm and includes AES 128bit data encryption and a built-in temperature sensor.

Conclusion

The Industrial Internet of Things forms part of the larger ‘Internet of Everything’ but it is a significant part; some analyst figures suggest it could represent more than half of what will be considered the IoT in future years.

The potential benefits of adopting the IIoT in terms of increased productivity alone mean its rise is realistically inevitable. Secondary to that, the possible impact of having so much performance data at hand could provide an exponential improvement in the cost-effectiveness of all future industrial applications.

The first step on that journey will be connecting existing devices to cloud-based services, and wireless connectivity in the form of pre-certified modules is emerging as the frontrunner in realising that goal. With a wide range of modules available and, undoubtedly, more on the way, enabling your existing and future industrial applications to benefit from the IIoT could be almost a ‘Plug & Play’ process.