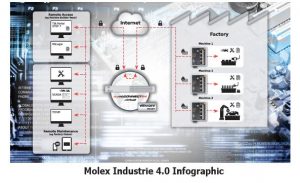

Unless you have been hiding away there is no escaping the fact that industry 4.0 and the Internet of Things (IoT) is constantly in the news globally. We are already seeing machine builders and high-end manufacturers applying these techniques to create intelligent, connected industrial machines and systems. These link directly from office to device to deliver clear advantages in terms of cost and risk reduction, enhanced performance and flexibility as well as opening up new service opportunities.

Here at Molex we see engineers facing the challenge of ensuring that vital maintenance is carried out as machines and manufacturing lines become even more complex. Traditionally, rapid response and versatile troubleshooting, based on in-depth knowledge and familiarity with the plant, have been the stock-in-trade of successful maintenance engineers. As these machines and systems integrate more intelligent technology, their complexity makes them increasingly difficult to maintain. Globalisation compounds this as they can be located anywhere in the world. The issue here is that as use of intelligent technology increases they become more difficult to maintain.

But Industry 4.0 technologies also present new possibilities to help address these maintenance challenges. These same intelligent sensing, connectivity and communications capabilities can also enable new maintenance and service opportunities. In contrast to the traditional preventive approach, based on predetermined maintenance and fixed intervals or duty cycles, operational machine and sensor data is continuously monitored, collected and analysed in real-time. Stored in the cloud with appropriate levels of security, this data can be accessed remotely from anywhere in the world, using a computer, tablet or smartphone. Specialist software flexibly monitors and analyses the data, triggering alerts based on defined rules and parameters, notifying the correct team member depending on the requirement, perhaps even assigning digital service tickets.

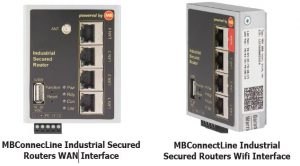

Molex and MB connect line have collaborated to create solutions to address these increased maintenance challenges. Industrially hardened and secured routers installed directly on the machine provide the required level of remote access, via Ethernet or Wi-Fi communications, with security built-in. This enables engineers to access machines in real-time, anywhere in the world, opening up new possibilities for commissioning, configuration and diagnostics, as well as over-the-air firmware and software updates. By enabling simple, secure and reliable end-to-end remote access, machine and system builders can reduce travel and maintenance costs, as well as improve resolution times when problems arise.

Cybersecurity and privacy is a critical concern for our industry, as many systems are weak by design. By controlling data traffic to and from the machine via VPN and encrypted connections we provide the highest standards of cybersecurity. All of our routers embed firewalls, which are backed by regular and rigorous penetration audits carried out by third-party security companies. For enhanced privacy and complete control over data and accesses, a private version of the RSP can be installed on customer’ company servers.

There can be no doubt that remote access will open up new possibilities for maintenance and service. Collecting usage and life-cycle data is also enormously valuable, feeding back into bug-fixing, product refinement and development processes. Molex and MB connect line are focusing their efforts on providing machine builders, integrators and manufacturers with remote access solutions to improve their competitiveness, increasing efficiency, enhancing flexibility and shortening time-to-market. Secure remote access will also help them to differentiate themselves, adding value by supporting their end-customers with efficient and cost-effective maintenance contracts and services.