The manufacturing industry is on the cusp of a 4th wave of transformation that holds the promise of a step change in productivity. Industrial IoT business models are being defined with increased flexibility, cooperative human-machine interaction and the use of data analytics to discern trends and dynamic system relationships previously hidden or inaccessible.

Fig 1. The image shows a TSN (Time Sensitive Network) testbed courtesy of National Instruments and the IIC

Advances in Industrial Automation technology realizes the ambition of Industrial IoT and promises great opportunities for manufacturers to compete in the global economy through increased productivity, safety, and reliability while reducing emissions. In fact, the manufacturing sector represents the most significant and largest Industrial IoT opportunity today. It is estimated that over the next 10 years IoT & the Digital Transformation is currently estimated at ~$20 Trillion of which Manufacturing represents the largest at ~$6.5T. Unsurprisingly, Automation equipment makers are trying to capture more value with additional IIoT related software and services.

While the opportunity is attractive, there are significant headwinds. For example, adoption of new technology in this traditionally conservative moving industry can be slow. Automation plants today are often a mix of newer and legacy systems with the associated complexity in inter-system communications. Capturing and communicating data securely from the edge of the network remains largely out of reach with the existing infrastructure. In short, factories and process plants will not transform overnight and a transition is required.

To enable and accelerate this transition, Automation vendors are turning to technology partners and suppliers like Analog Devices to provide more system domain expertise and solutions.

The transition required for the Connected Enterprise and in particular, Ethernet and Security

Industrial Ethernet is already widely used in control applications and continues to expand as the preferred communication medium as industries transition towards greater connectivity and the realization of the Industrial Internet of Things (IIoT).

Many Industrial protocols solve the problem of determinism over Ethernet using proprietary layer 2 solutions which can cause significant interoperability issues when attempting to extract relevant data for usage at the higher levels of the enterprise network or coordinate between disparate manufacturing nodes. The new IEEE 802.1 TSN standards are aimed at the same class of problems encountered in industrial control and promise to enable a transition from proprietary solutions in favor of a standards-based approach.

Ethernet has traditionally been a “best-effort” network. To allow Ethernet to be deployed in mission critical applications, it is necessary to add specific features including time synchronization, scheduled traffic, ingress policing, seamless redundancy and others. The goal behind these emerging IEEE TSN standards is to achieve a truly converged network where all classes of traffic can seamlessly coexist. This would allow mission critical real-time traffic to coexist on the same network as streaming traffic and best-effort traffic. These features allow network designers to ensure that certain classes of traffic can be delivered on time, every time throughout the entire network topology. Unlike proprietary layer 2 solutions, these features are designed to be scalable to gigabit line rates and beyond.

Connecting edge devices to the converged Trusted IIoT Connected Enterprise networks, enabled by TSN, raises many challenges. Current communication technologies in edge devices (e.g. Fieldbus and 4-20mA current loops) work and they work reliably. However, getting their data to the cloud (local or remote) is often obfuscated by the many layers of communication along the path from the factory floor to the front office. Gateways are often needed to translate from one format or protocol to another and the data may be stored on multiple servers on its journey to where data analytics actually happen. The total ownership cost to get data from a simple sensor to the cloud not only involves the equipment necessary for data delivery, but also the software, processing and manpower necessary to ensure data integrity along the way.

While it may seem contradictory to bring Ethernet to such a simple device like a temperature transmitter, it isn’t about the simplicity of the device or the relatively small amounts of data produced or consumed by the device. It’s about the ability to cost effectively extract the data from the device on a converged network and then using that data for actionable results. For example, a Distributed Control System (DCS) might use temperature data from the temperature transmitter to ensure its part of the process is running in control in real-time. However, there could also be implications of this specific temperature on the overall process. With a temperature transmitter seamlessly connected to the cloud, analytics can be performed considering all process parameters in near real-time to ensure the overall process is running. Adjustments can be made so production can be optimized or energy efficiency can be increased.

ADI views these challenges as key to our customers’ success and the motivating factor for our investment in cutting edge technologies to drive Ethernet to the edge. One key enabling technology we call “Low-complexity Ethernet” is a driver for bringing simple industrial devices like a temperature transmitter directly to an Ethernet network. Low-complexity Ethernet solves the traditional size, power, and cost issues of today’s standard layer 2 Ethernet implementations in order to bring down the total ownership cost of getting data to the cloud.

The transition to a converged industrial Ethernet network also needs innovation at the physical layer to deliver a solution that matches some of the inherent capabilities of the incumbent systems. Many of the most widely deployed Ethernet physical layer standards are limited to 100 meter cable length and require multiple twisted pair cables to implement. By contrast, much of the existing installed base of factory automation network infrastructure is built on single twisted pair cabling that can extend beyond 1000 meters in length at a data rate of 31.25kb/s. To help address this, ADI is working with key industrial partners under the auspices of the IEEE to develop a new Ethernet standard, 10SPE that will operate over a single twisted pair cable, up to 1000m and at a data rate of 10 Mb/s. By taking a collaborative, standards-based approach to solving this problem, ADI is assisting in the lowering of barriers to adoption of this new capability and shortening the timeframes in which the goal of a converged, plant-wide network can be achieved.

In addition to the development of new capabilities to enable Ethernet convergence, other applications that have a more established usage of deterministic Ethernet at 100Mb/s are pushing the limits of bandwidth and performance. Applications such as robotics are demanding an ever increasing number of coordinated axes, controlled at greater precision than previously possible. Transitioning the control network to gigabit speeds helps satisfy these requirements and represents another major trend in the industrial Ethernet market.

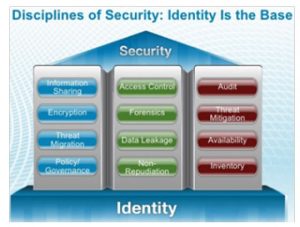

Ethernet’s meteoric success has often left users of Ethernet technologies struggling to address security concerns associated with its application. The anticipated increase in demand for data and sensing at the edge of the Industrial network may be hampered by the perceived risks related to security. Further, the requirements for low latency and jitter in industrial control applications can be in direct conflict with the requirements for security. It is incumbent upon users of these technologies to address concerns regarding performance and security in these applications sooner rather than later.

Cyber Security Risks in the Industrial space are getting more attention every day. Due to the emergence of Industry4.0 and IIoT, the Industrial space is moving to an unprecedented environment of widely distributed devices, dynamic information flows, and connectivity across environments to provide new capabilities. However, it is no surprise that along with creating new capabilities, it also creates new security threats previously unthought-of, but more REAL than ever.

If one imagines the sheer number of devices that must be securely connected to the network, it becomes clear that establishing the identity of these devices becomes problematic. Physically distributed shared encryption keys quickly becomes impractical and management of certificates-exchanges a logistics nightmare. Keyless establishment of identity is vital if the vision of the Trusted IIoT Connected Enterprise is to be realized. Likewise, lightweight encryption techniques, with low, fixed latency, and a small hardware and/or software footprint will be needed to securely connect the highly constrained devices at the edge of the network. ADI has invested heavily in technologies like Identity Authentication and security solutions for resource constrained devices and lightweight block cryptography to address these important issues.